308986

11

Installation

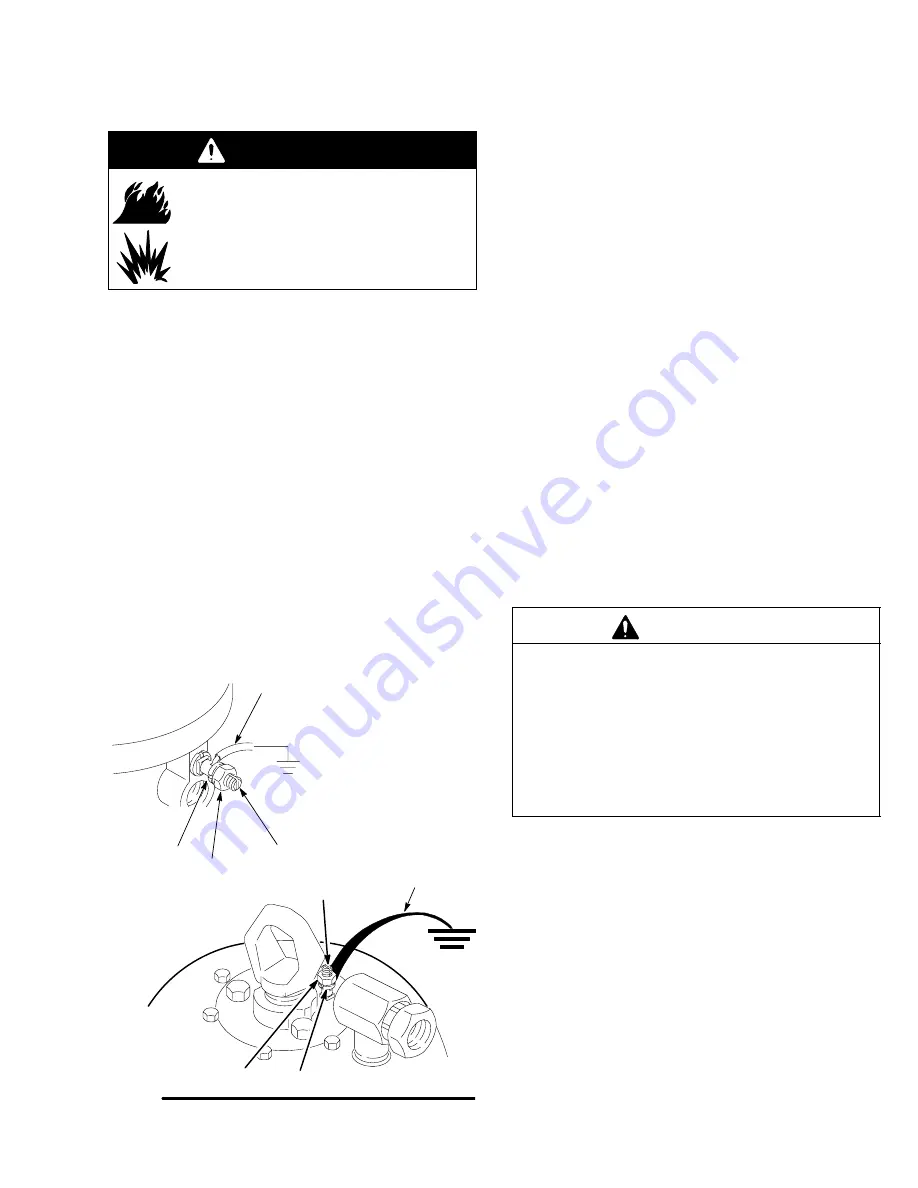

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding could cause static

sparking, which could cause a fire or

explosion. To reduce the risk of property

damage or serious injury, follow the

grounding instructions below.

The following grounding instructions are minimum

requirements for a system. Your system may include

other equipment or objects which must be grounded.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment. Your

system must be connected to a true earth ground.

1.

Pump:

a.

Loosen the grounding lug locknut (Fig. 4,

Item BB) and washer (AA).

b.

Insert one end of a 14 ga. (1.5 mm

@

) minimum

ground wire (G) into the slot in lug (CC) and

tighten the locknut securely.

c.

Connect the other end of the ground wire to a

true earth ground.

Fig. 4

G

BB

AA

CC

G

BB

AA

CC

Select you application

Available Accessories (must be

purchased separately)

1.

Air hoses:

use only grounded hoses with a maxi-

mum of 500 feet (150 m) combined hose length to

ensure grounding continuity.

2.

Air and Paint Line Filters:

locate all filters and

learn all filter cleaning procedures before operating

the system. Optional filters are available to meet

particular system needs. Be sure all filters are

checked and cleaned every day.

3.

Filters:

be sure your hydraulic power supply (U) is

equipped with a suction filter to the hydraulic pump

and a system return line filter (S) of 10 micron size.

Carefully follow the manufacturer’s recommendations

on reservoir and filter cleaning, and periodic changes

of hydraulic fluid. Use only Graco approved hydraulic

oil. Order Part No. 169–236, 5 gallon (19 liter) or

207–428, 1 gallon (3.8 liter).

4.

Hydraulic Line Accessories:

on the hydraulic

supply line (Item C, Fig. 3), install the following

accessories in the order shown in Fig. 3, using

adapters as necessary.

CAUTION

It is very important to keep the hydraulic supply

system clean at all times. Be sure that all hydraulic

fluid lines are absolutely clean. Blow out the lines

with air and flush thoroughly with solvent before

connecting to the hydraulic motor, to avoid introduc-

ing harmful contaminants into the motor.

For optimum pump performance, keep the tempera-

ture of the hydraulic oil below 130

_

F (54

_

C).

a.

Shutoff valve (P): to isolate the pump for

servicing.

b.

Fluid pressure gauge (F):

to monitor hydraulic

oil pressure to the motor and to avoid over-

pressurizing the motor or displacement pumps.

c.

Pressure and temperature-compensated flow

control valve (G): to prevent the motor from

running too fast and possibly damaging itself.

d.

Pressure reducing valve (H) with drain line (E):

running directly into the hydraulic return

line (D).

e.

Accumulator (J): to reduce the hammering

effect caused by the motor reversing direction.

Summary of Contents for HYDRA-CAT FIXED RATIO

Page 38: ...38 308986 Notes...

Page 39: ...308986 39 Notes...