Setup

16

313888E

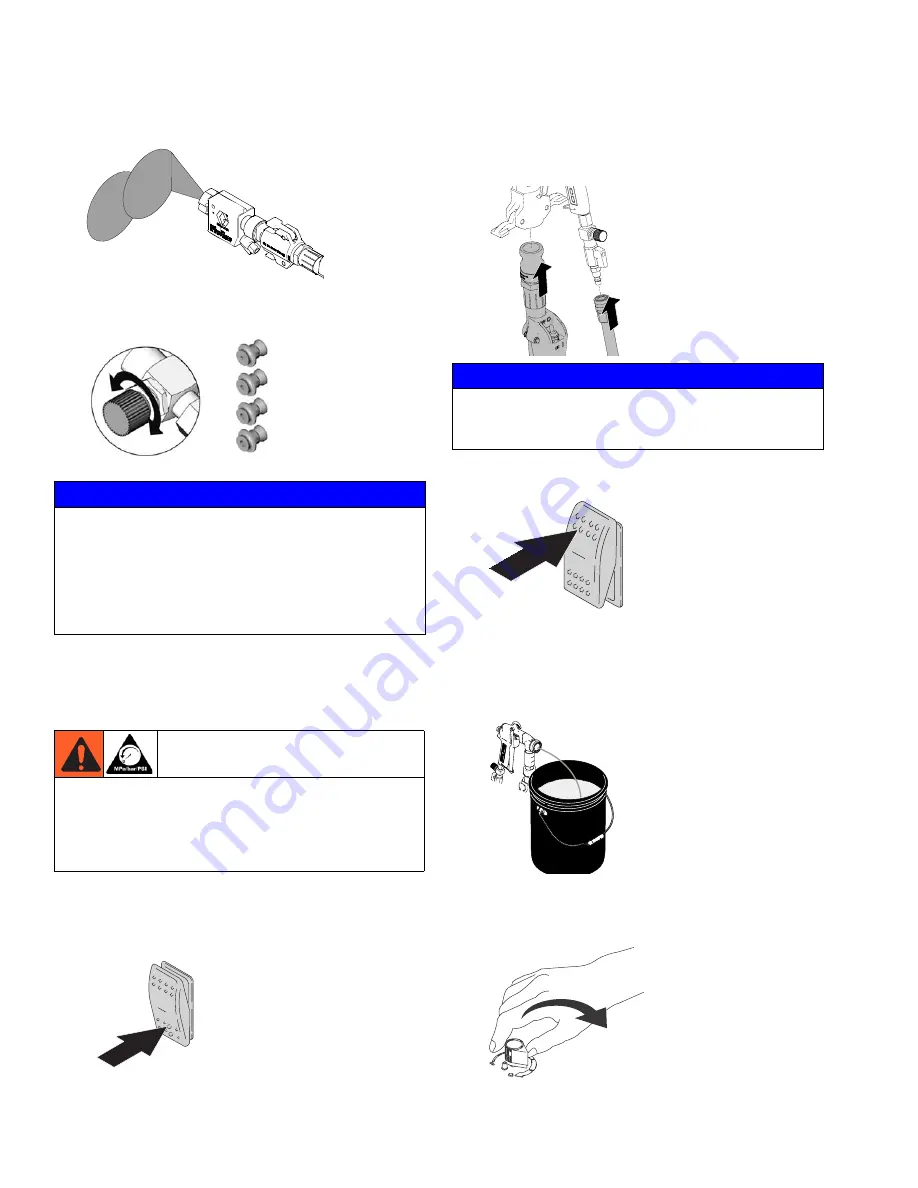

8.

Spray test pattern. Aim applicator at floor. Turn air

valve ON. Move applicator to spray surface.

9.

Adjust air valve and/or select alternative nozzle size

(4 - 10mm) for desired finish.

Air Assisted Spray

(Air Spray Trigger Gun)

1.

Prepare material, page 13. Place material hose in

supply pail.

2.

Turn on/off switch OFF.

3.

Turn air valve OFF. Connect applicator to material

hose and air hose. Air supply minimum require-

ments vary with material thickness and desired

thickness.

4.

Turn on/off switch ON.

5.

Hold applicator over material pail, trigger on, and

turn pump ON using applicator switch on hose.

NOTE:

Remove spray disk then set material flow to

prevent material from back-flowing into air passages

of gun.

6.

Turn pump control clockwise and adjust engine

throttle to lowest setting until desired material deliv-

ery rate is achieved.

NOTICE

IF PUMP IS STOPPED LONGER THAN 3 MIN-

UTES, TO AVOID PUMP PLUGGING:

•

Relieve pressure in the pump (See Pressure

Relief procedure - page 10).

•

Recirculate the material by pumping back into

original material container.

Due to the high pressure fluid emitted, a strong recoil

action may occur when you trigger this gun. If you are

unprepared, your hand could be forced back toward

your body or you could lose your balance and fall,

resulting in serious injury.

ti13646a

ti11798a

6 mm

8 mm

10 mm

4 mm

ti10796b

NOTICE

DO NOT USE MATERIALS THAT CURE RAPIDLY!

Materials with a fast curing time could plug the pump

hose, gun, or applicator.

ti21263a

ti10795b

ti21243a

ti8794a

Summary of Contents for HTX 2030

Page 26: ...Notes 26 313888E Notes ...

Page 27: ...Notes 313888E 27 Notes ...