8

IO-230F

08/04

To increase the superheat (measured at the condenser

base valve), turn the stem clockwise (in). Similarly, to

decrease the superheat, turn the stem counterclockwise

(out). Use a ¼ “ refrigeration wrench for this function.

Note:

Design point for the system is 10 degrees of

superheat (measured at the condenser base valve) at 95

degree outdoor air.

Charging Note:

Air handlers with TXV’s (ARPT’s and

AEPT’s) should be charged to 15 degrees of subcooling at

the indoor inlet. This supercedes any subcooling value

listed with condensing unit’s literature.

AEPT MOTOR ORIENTATION

If the unit is in the upflow position, there is no need to rotate

the motor. If the unit is in the downflow or horizontal position,

loosen motor mount and rotate motor as shown in Figure

4. Be sure motor is oriented with the female connections

on the casing pointing down. If the motor is not oriented

with the connections pointing down, water will collect in

the motor and cause premature failure.

FRONT VIEW

FOR OPTIONAL

SAFETY GND USE

MOUNTING BOLTS

SIDE VIEW

FEMALE CONNECTIONS

Figure 4

AEPT Motor Orientation

CONVERSION TO DOWNFLOW

The ARPF “B” series product is factory equipped for

downflow operation and no field conversion is required. It

is recommeneded that the conversion to downflow be

performed before placing the air handler in its final location

and in an area that allows for access to all sides. To prevent

the evaporator coil pan from “sweating” the DPI accessory

insulation kit is to be used when performing this conversion.

Note: The DPI kit is not supplied with this product and is to

be purchased separately. See Table 8 for the correct DPI

kit.

ARUFor ARPT

model

AEPT model

Insulation Kit

018-032

n/a

DPI18-30/20

036-042

30

DPI36-42/20

048-061

036, 060

DPI48-61/20

Table 8

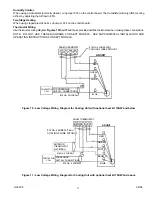

Refer to

Figures 5 through 7

for the location of the

components referenced in the following steps.

Figure 5

illustrates the new installation location for the removed

components.

1.

Before inverting the air handler, remove all access

panels, the coil rear channel bracket, and the filter

close-off panel.

2.

Remove the evaporator coil and the horizontal drain

pan. Discard horizontal drain pan.

3.

Install the provided plastic plug into the vacated access

panel.

4.

Remove the two (2) zee coil support brackets and

insulation retaining brackets.

5.

Remove the tie bracket.

6.

Install the DPI Insulation Kit onto the bottom of the drain

pan.

Return Air Side

of Unit

Rear

Channel

Bracket

Zee Coil

Support Bracket

Access

Panel

Coil Retaining

Bracket

NOTE: The filter provision is not applicable

in THIS downflow application.

Tie Bracket

Figure 5

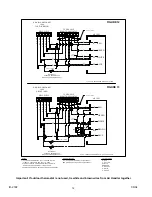

7.

Install the zee coil supports and the wrapper stiffeners.

8.

Install the tie bracket.

9.

Install the rear channel bracket.

10. To prevent possible condensate “blow off” the insulation

retainers are to be laid into the evaporator coil pan as

shown in

Figure 6.

3" Flat Insula tio n

R e taine r (B o th Sides)

Figure 6