10

IO-230F

08/04

IMPORTANT NOTE: THE EVAPORATOR COIL IS

COATED WITH OILS THAT MAY DISSOLVE

STYROFOAM AND CERTAIN TYPES OF PLASTICS.

THEREFORE, A REMOVAL PUMP OR FLOAT SWITCH

MUST NOT CONTAIN ANY OF THESE MATERIALS.

Tip

: Priming the “P” trap may avoid improper draining at

the initial installation and at the beginning of the cooling

season.

ACHIEVING 2% LOW LEAKAGE RATE

Ensure that the Neoprene gasket with PSA remains intact

on all surfaces that the access panels are secured to.

These surfaces are the entire length of the wrapper and

areas between the upper tie plate, upper and lower access

panels. Be sure that upper access panel breaker insert

gasket is intact and also flowrator gasket is installed on

the lower access panel. An additional drain hole cover is

required.

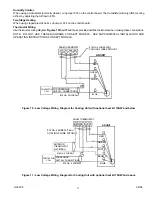

ARUF/ARPF MOTOR

Motor Speed Adjustment

The motors in all ARUF and ARPF motors are multi-speed

PSC motors. The color of the wire coming from the motor

to the “COM” terminal on the control board defines in which

speed the motor will operate. The black wire represents

high speed, the red wire represents low speed, and the

blue wire (select models only) represents medium speed.

To change speeds, remove the wire attached to the “COM”

terminal on the control board, and swap it with the wire (on

terminal “M1” or “M2”) with the color that will give the

desired speed.

NOTE: In some models, not all speed taps are allowable

for certain electric heat applications. Refer to air handler

Series and Ratings plate for minimum speed.

AEPT MOTOR

This section references the operation characteristics of

the AEPT model motor only. The ECM control board is

factory set with dipswitch #4 in the “ON” position and all

other dipswitches in the “OFF” position.

For most

applications this setting is to be changed according

to the electric heat size and the outdoor unit selection.

The AEPT product uses a General Electric ECM

TM

motor.

This motor provides many features not available on the

traditional PSC motor. These features include:

• Improved Efficiency

• Constant CFM

• Soft Start and Stop

• Improved Humidity Control

Motor Speed Adjustment

Each ECM

TM

blower motor has been preprogrammed for

operation at 4 distinct airflow levels when operating in

Cooling, H.P. Heating, Backup Heating (Electric Heating),

and H.P. Heating. Each mode has 4 levels to

deliver different Air Flow CFM [L/s]. The adjustment is

performed by changing the dipswitch(s) either to an “OFF”

or “ON” position.

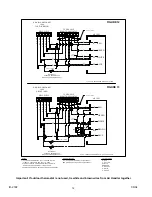

Dipswitch Functions

The AEPT air handler motor has an electronic control that

contains an eight (8) position dip switch. The function of

these dipswitches are shown in

Table 9

.

Dipswitch Number

Function

1

2

3

N/A

4

Indoor Thermostat

5

6

7

8

Cooling & Heat Pump CFM

CFM Trim Adjust

Table 9

Electric Heat

CFM Delivery

Tables 10

and

11

show the CFM output for dipswitch

combinations 1-2, and 5-6.

Switch

Switch

1

2

OFF

OFF

1100

1210

ON

OFF

850

935

OFF

ON

700

775

AEPT36

OFF

OFF

2050

2150

and

ON

OFF

1750

1835

AEPT60

OFF

ON

1600

1680

ON

ON

1200

1260

Model

TABLE 10 - ELECTRIC HEAT CFM

AEPT30

EMERGENCY

(ELECTRIC)

HEAT

HP

w/BACKUP

HEAT

Switch Switch

5

6

OFF

OFF

2 ½

1100

ON

OFF

2

800

OFF

ON

1 ½

600

AEPT36

OFF

OFF

5

1800

and

ON

OFF

4

1580

AEPT60

OFF

ON

3 ½

1480

ON

ON

3

1200

Table 11 - Cooling and Heat Pump CFM

Nominal Cooling

Tonnage

AEPT30

Model

CFM

Thermostat “Fan Only Mode”

During “Fan Only Mode” operation, the CFM output is 30%

of the cooling setting.

CFM Trim Adjust

Minor adjustments can be made through the dip switch

combination of 7-8. The following

Table 12

shows the

switch position for this feature.

CFM

Switch 7

Switch 8

+10%

ON

OFF

-15%

OFF

ON

Table 12