13

IO-230F

08/04

Quality Makes the Difference!

All of our systems are designed and manufactured with the same high quality standards

regardless of size or efficiency. We have designed these units to significantly reduce the

most frequent causes of product failure. They are simple to service and forgiving to operate.

We use quality materials and components. Finally, every unit is run tested before it leaves

the factory. That’s why we know. . .

There’s No Better Quality.

Visit our websites at

www.goodmanmfg.com

or

www.amana-hac.com

for information on:

•

Products

•

Warranties

•

Customer Services

•

Parts

•

Contractor Programs and Training

•

Financing Options

© 2003-2004 Goodman Manufacturing Company, L.P.

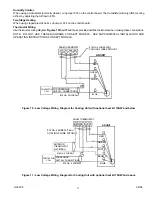

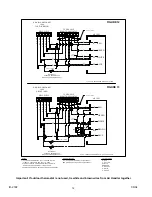

THERMOSTATS

Note: Second Stage heat can be accomplished by multi-

stage heating thermostat or the addition of an outdoor

thermostat as shown in Figures 12 and 13.

Goodman part number CHT18-60 is a single-stage cool

and single-stage heat thermostat.

Goodman part number HPT18-60 is a single-stage cool,

two-stage heat pump thermostat. The first stage is heat

pump heating and the second stage is optional electric heat.

If additional features are desired, such as digital or

programmable capabilities, these thermostats are

commercially available. Follow the thermostat

manufacturer’s instruction for installation.

START-UP PROCEDURE

•

Prior to start-up, ensure that all electrical connections

are properly sized and tightened.

•

All panels must be in place and secured. For Air Tight

application, neoprene gasket must be positioned at

prescribed locations to achieve 2% leakage.

•

Tubing must be leak free.

•

Unit should be elevated, trapped and pitched to allow

for drainage.

•

Low voltage wiring is connected.

•

Auxiliary drain is installed when necessary and pitched

to allow for drainage.

•

Drain pan and drain tubing has been leak checked.

•

Return and supply ducts are sealed.

•

Unit is elevated when installed in a garage or where

flammable vapors may be present.

•

Unit is protected from vehicular or other physical

damage.

•

Return air is not obtained from any areas where there

may be objectionable odors, flammable vapors or

products of combustion such as carbon monoxide

(CO), which may cause serious personal injury or

death.

REGULAR MAINTENANCE

WARNING

DISCONNECT ALL POWER SUPPLIES BEFORE

PERFORMING ANY SERVICE. NOTE THAT THERE MAY

BE MORE THAN ONE POWER SUPPLY. FAILURE TO

OBSERVE THIS WARNING CAN RESULT IN ELECTRICAL

SHOCK THAT CAN CAUSE PERSONAL INJURY OR

DEATH.

The only item to be maintained on a regular basis by the

user is the circulating air filter(s). Filter should be cleaned

or replaced regularly. A certified service technician must

perform all other services.