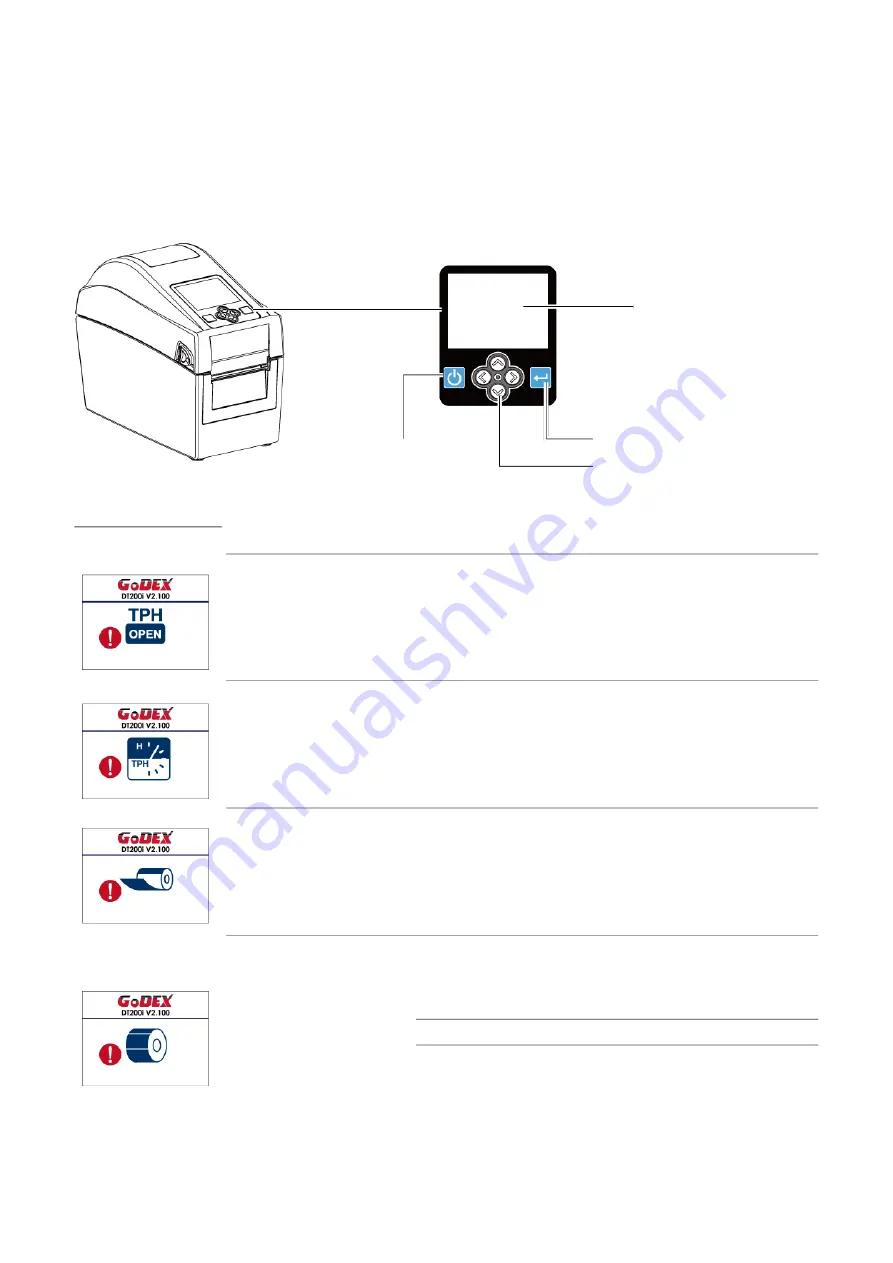

OPERATION PANEL

LCD Screen

Power Button

Feed key

Direction key

Operation Panel

Status

Type

Beeps

Description

Solution

Print head

Error

2 x 4 beeps

None

Media Error

2 x 3 beeps

2 x 2 beeps

The printing mechanism

is not correctly closed.

Open the print mechanism

and close it again.

High temperature at

the print head.

Once the print head has

cooled down, the printer

switches to standby mode.

No ribbon is installed and

the printer displays an error.

Make sure that the

printer is set to direct

thermal printing mode.

No paper is detected.

Make sure that the label sensor

is positioned correctly. If the

sensor still does not detect the

paper,run the auto-detection

function again.

Replace the label roll.

Possible reasons: the print

medium has become trapped

around the rubber roll; the sensor

cannot detect a gap or black mark

between the labels; there is no

paper. Please reset the sensor.

C

heck ribbon setting

TPH overheat

THP opened

Check paper setting

Print head

Error

Media Error

No paper is detected.

No paper is detected.

3.9 Error Alerts (DT200i/DT200iL Series)

In the event of a problem that prevents normal functioning of the printer, you will see an error message on LCD

screen and hear some beep signals. Please refer to below table for the error alerts.

Summary of Contents for DT200 Series

Page 7: ...Bottom View Specifications of the wall mounted screws Bottom cover Mounting points ...

Page 16: ...3 After selecting the folder to install click Next 4 Click Next to start the installation ...

Page 17: ...5 Finish installation ...

Page 19: ...3 Select the path to unzip and click Next 4 Click Finish and open the Driver Wizard ...

Page 21: ...7 After confirming the settings click Finish to install ...