48

CHAPTER 7

Understanding Messages

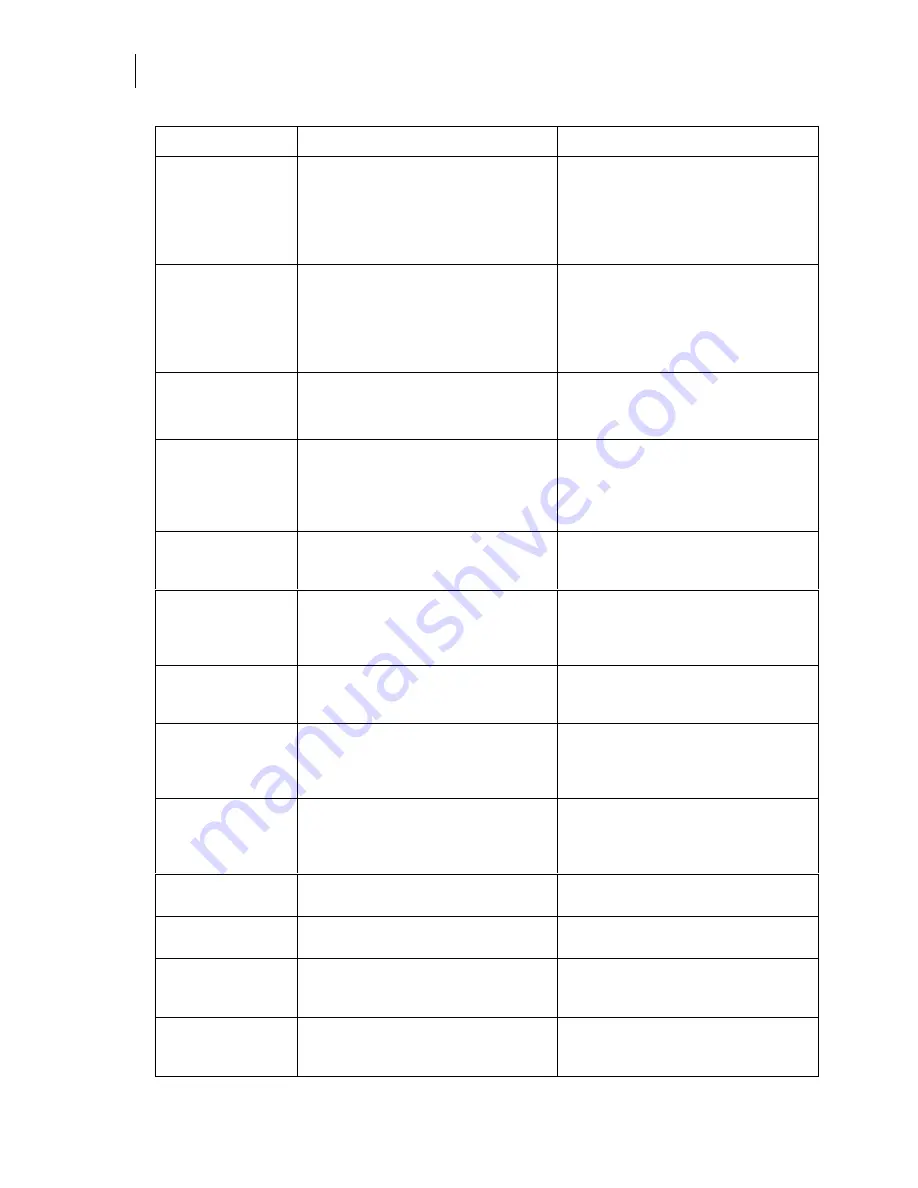

Error message

Meaning

Action

Foil Write Error, Bay

“#”

Unable to write the foil button in bay

“#” after unloading that foil.

Ensure the cassette is properly seated in

the bay, and tap the supply roll to

correct a possible contact problem with

the button. If error still occurs, try

loading a different foil. If error goes

away, the button on the first foil is bad.

Foil Write Verify

Error

Cannot read foil button to verify what

was just written.

Ensure the cassette is properly seated in

the bay, and tap the supply roll to

correct a possible contact problem with

the button. If error still occurs, try

loading a different foil. If error goes

away, the button on the first foil is bad.

Illegal Command in

Job

Firmware encountered an unknown

command in the job data. The job is

aborted.

Re-render the job and re-send it to the

printer.

Illegal Data

Compression

The job compression format is

unknown. The MAXX 2 accepts only

jobs that are compressed in LZW format

or uncompressed image data. The job

is aborted.

Re-render the job and re-send it to the

printer.

Illegal Job Format

This usually occurs when an old version

of OMEGA or GA has been used to

create the job. Job is aborted.

Load the current version of OMEGA,

re-render the job and re-send it to the

printer.

Internal Y Position

Error

Vinyl has shifted too far to the left of the

guide mark during a print job.

Check the vinyl edge for damage.

Replace vinyl. If the error still occurs, the

vinyl sensors may be dirty. Contact

Gerber Field Service.

Material Twisted

The material may not be perfectly

straight. The job pauses.

You can continue printing at your own

risk or stop the job, fix or replace the

vinyl and reprint job.

Missing Fire Control

Data

Embedded fire control information is

not in job. This usually occurs when an

old version of OMEGA or GA has been

used to create the job. Job is aborted.

Load the current version of OMEGA,

re-render the job and re-send it to the

printer.

Missing History

Control Data

Embedded history control information

not in job. This usually occurs when an

old version of OMEGA or GA has been

used to create the job. Job is aborted.

Load the current version of OMEGA,

re-render the job and re-send it to the

printer.

Reminder to Change

Head Cleaning Pad

Displayed to remind the user to remove

the used the head-cleaning pad.

Remove the topmost head-cleaning

pad.

Time Out Sending

Command

PC fails to receive acknowledgement in

a reasonable amount of time

Cycle power. If error continues, contact

Gerber Field Service.

Time Out Waiting

For A Stop

PC fails to receive notification of the

A-axis stop in a reasonable amount of

time.

Cycle power. If error continues, contact

Gerber Field Service.

Time Out Waiting for

Axes Stop

PC fails to receive notification of the

axes stop in a reasonable amount of

time.

Cycle power. If error continues, contact

Gerber Field Service.

Summary of Contents for 2

Page 1: ...GERBER MAXX 2 Owner s Guide ...

Page 2: ......