84

GERBERplotter MP Series User Manual

English

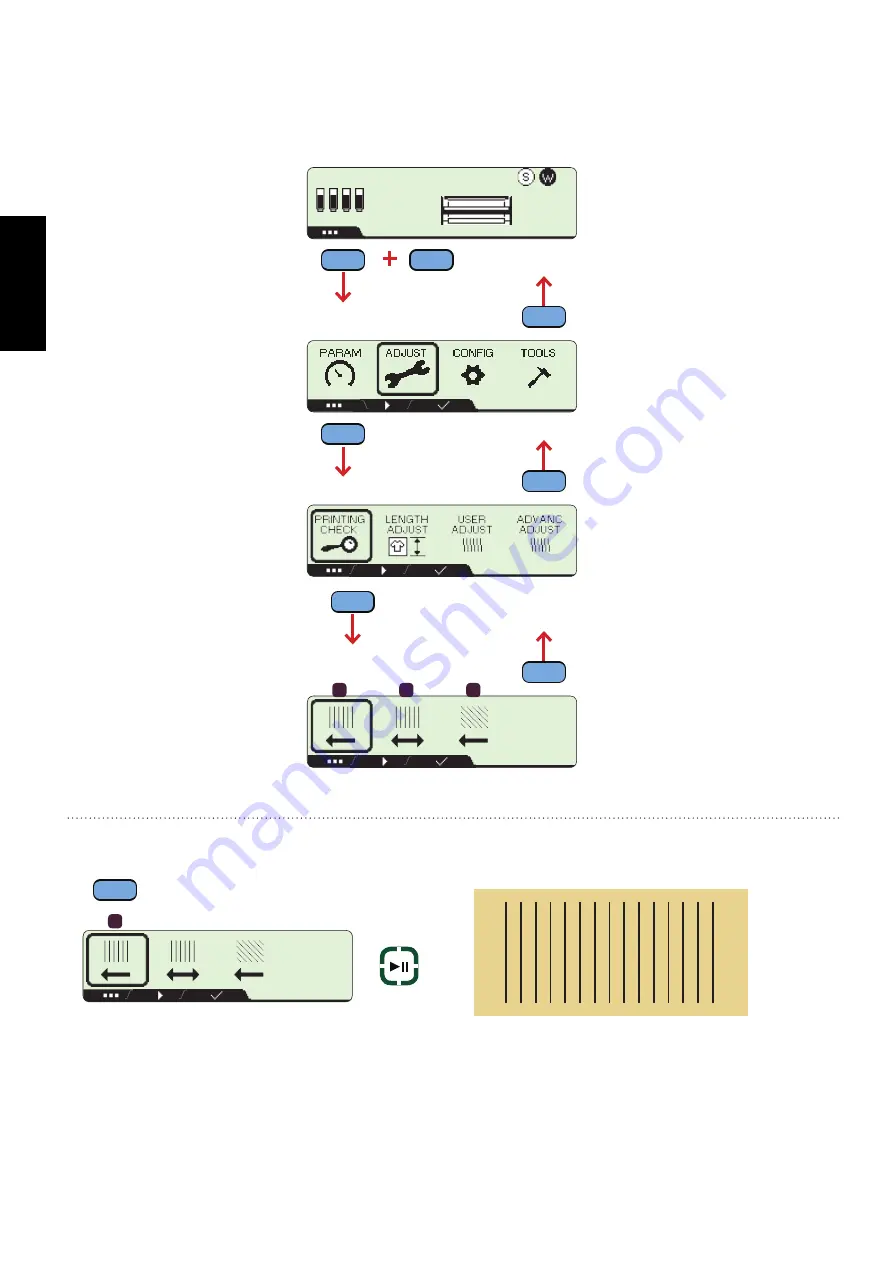

5.4.3 Print tests

The first option in the ADJUST menu is the PRINTING CHECK, which allows you to perform a series of printing

tests.

This option checks that all the print heads function correctly.

1

Prints unidirectional continuous lines. This verifies the print in one direction.

OK

1

2

3

K

K

K

K

19:49

MENU

MENU

MENU

OK

MENU

Continuous lines in one or both print directions.

1

OK

PAUSE

Summary of Contents for GERBERplotter MP Series

Page 1: ...GERBERplotter MP Series User Manual...

Page 2: ......

Page 3: ...GERBERplotter MP Series User Manual...

Page 4: ......

Page 6: ...English GERBERplotter MP Series User Manual ii...

Page 10: ...English GERBERplotter MP Series User Manual vi...

Page 12: ...2 GERBERplotter MP Series User Manual English...

Page 18: ...8 GERBERplotter MP Series User Manual English...

Page 44: ...34 GERBERplotter MP Series User Manual English...

Page 46: ...36 GERBERplotter MP Series User Manual English...

Page 65: ...55 GERBERplotter MP Series User Manual English 4 Updating WinPlot or AccuMark...

Page 66: ...56 GERBERplotter MP Series User Manual English...

Page 72: ...62 GERBERplotter MP Series User Manual English...

Page 74: ...64 GERBERplotter MP Series User Manual English...

Page 122: ...112 GERBERplotter MP Series User Manual English...

Page 158: ...148 GERBERplotter MP Series User Manual English...

Page 160: ...150 GERBERplotter MP Series User Manual English...

Page 172: ...162 GERBERplotter MP Series User Manual English...

Page 174: ...164 GERBERplotter MP Series User Manual English...

Page 179: ...169 GERBERplotter MP Series User Manual English 9 Glossary...

Page 180: ...170 GERBERplotter MP Series User Manual English...

Page 183: ......