Publication No. GEG-99018A

Genicom

Nov 00

3-12

GENICOM LN28 and microLaser 280 User Guide

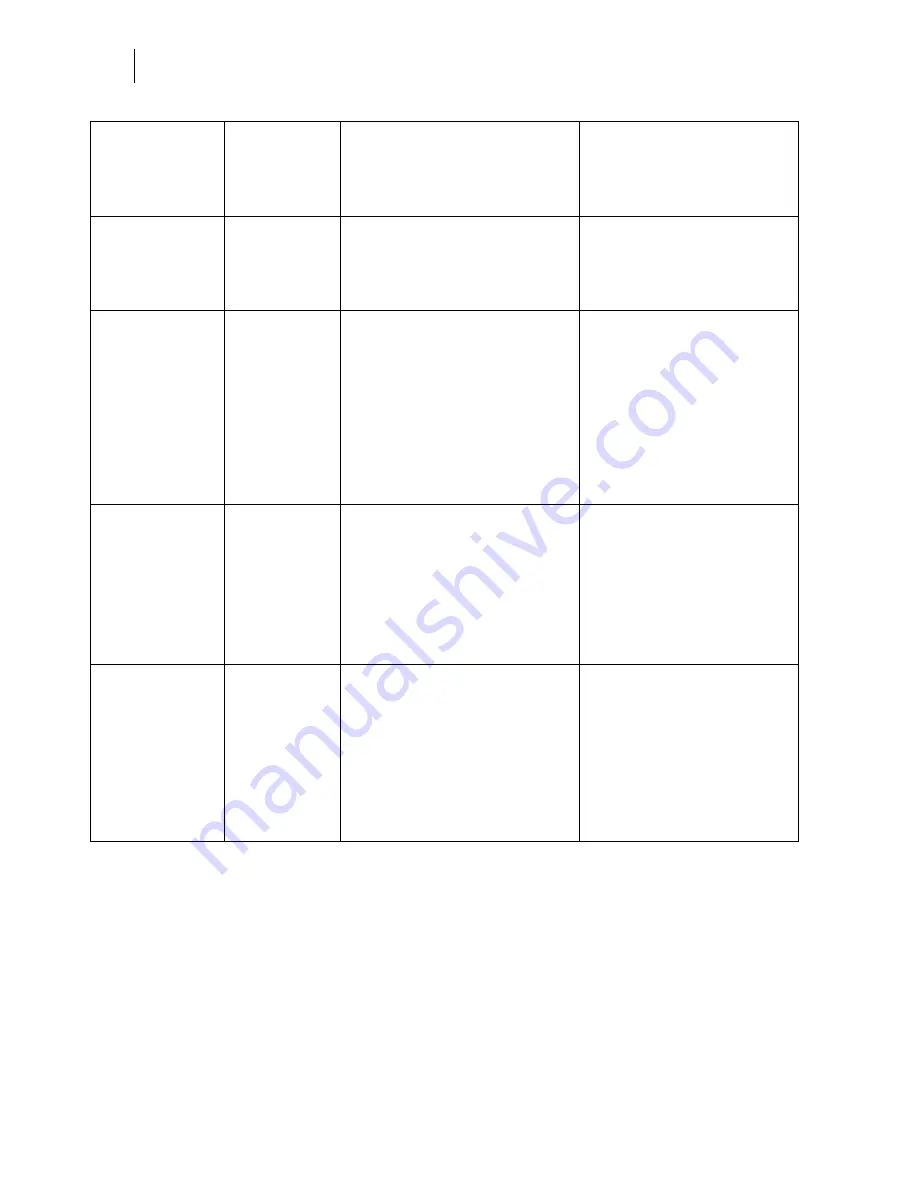

PCL Menu

Macro Filter

This submenu allows

you to turn the

macro filter on or

off.

Off

On

Off

1. Press NEXT or PREVIOUS to

toggle between ON and OFF.

2. Press SELECT to save this

setting.

Lines Per Page

This submenu allows

you to change the

number of lines per

page.

64

5 - 128

1. Press NEXT or PREVIOUS to

increase or decrease the lines

per page.

2. Press SELECT to save this

setting.

CR Mode

This submenu allows

you top define the

action prompted by

a carriage return—a

carriage return

equals either a

cariage return alone,

or a carriage return

and a line feed

together.

CR = CR

CR = CR

CR = CR/LF

1. Press NEXT or PREVIOUS to

choose from CR=CR or

CR=CR/LF.

2. Press SELECT to save this

setting.

LF Mode

This submenu allows

you to define the

action prompted by

a line feed—a line

feed equals either a

line feed alone or a

carriage return and

a line feed together.

LF = LF

LF = LF

LF = CR/LF

1. Press NEXT or PREVIOUS to

choose from LF=LF or

LF=CR/LF.

2. Press SELECT to save this

setting.

FF Mode

This submenu allows

you to define the

action prompted by

a form feed—a form

feed equals either a

form feed alone or a

carriage return and

a form feed

together.

FF = FF

FF = FF

FF = CR/FF

1. Press NEXT or PREVIOUS to

choose from FF=FF or

FF=CR/FF.

2. Press SELECT to save this

setting.

Summary of Contents for LN28

Page 1: ...Nov 00 Genicom Publication No GEG 99018A GENICOM LN28 and microLaser 280 User Guide SIB012F...

Page 3: ...Nov 00 Genicom Publication No GEG 99018A GENICOM LN28 and microLaser 280 User Guide iii...

Page 4: ...Publication No GEG 99018A Genicom Nov 00 iv GENICOM LN28 and microLaser 280 User Guide...

Page 12: ...Publication No GEG 99018A Genicom Nov 00 xii GENICOM LN28 and microLaser 280 User Guide...