5 - 6

Troubleshooting Guide

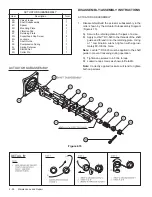

4.

Check for pilot gas pressure at on-stream chamber exhaust

valve’s pilot tubing connection.

If pilot pressure is present, Shutdown and Depressurize

Dryer. Disassemble, clean and inspect the Switching Valve.

Replace all worn or damaged parts as noted.

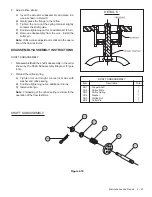

1.

Check indicator lights at solenoid block to determine whether

energized. Indicator light should be lit if the solenoid coil is

energized. If not, open control enclosure and check MEC

Board for output signal to solenoid valve.

a) If voltage is present and the indicator at the solenoid block is

not lit, Shutdown and Depressurize Dryer. Provide a

separate pilot gas source.

With the dryer controls de-energized, press the manual

override on solenoid valve to determine if functioning. If

functioning mechanically (the purge exhaust valve should

open), the solenoid valve coil is defective. Replace solenoid

valve coil.

Note: The dryer MUST be depressurized to change coils

on a solenoid.

b) If voltage is present and the purge exhaust valve doesn't

open when manual overriding the solenoid valve, the sole-

noid valve is defective. Replace solenoid valve.

c) If voltage is not present, replace MEC Board.

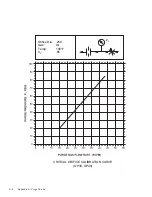

1.

Shutdown and Depressurize Dryer. Replace pressure sen-

sor.

4.

During Repressurization Cycle.

Purge Exhaust Switching Valve has failed to

close due to fouled or worn valve internals.

Valve Failure Alarm with excessive pressure ex-

hausting through muffler. BOTH chamber pres-

sure gauges read normal system pressure.

1.

During Depressurization Cycle.

Off-stream chamber's Purge Exhaust Valve

has failed to open due to the associated so-

lenoid valve's (A or D) failure to energize.

Valve Failure Alarm.

1.

Damaged or out of calibration pressure sen-

sor.

PROBLEM/POSSIBLE CAUSE

CHECKS AND REMEDY