Operation

3 - 1

3

Operation

through test and analysis when a specific quality pro-

cess gas is required.

4.

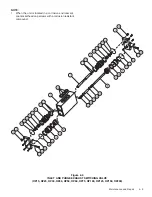

Refer to the applicable drawings which accompany

this manual as necessary for component identification

and location while conducting start-up and operational

procedures.

Note: If your dryer cannot be started, or fails to start

due to special installation or other problems, contact

your local General Pneumatics Sales Representative

for assistance.

5.

Close the customer-supplied System Inlet Isolation

Valve.

6.

Open customer-supplied System Bypass Valve, if in-

stalled.

7.

Close customer-supplied System Outlet Isolation

Valve.

8.

Supply compressed air up to Inlet Isolation Valve.

9.

Open Pilot Gas Supply Valve, located upstream of

the Pilot Gas Filter.

10. Supply pressure to system by SLOWLY opening Sys-

tem Inlet Isolation Valve (customer-supplied). Both

desiccant chamber Inlet Switching Valves will open

and both chamber Purge Exhaust Valves will close.

The desiccant chambers will immediately begin pres-

surizing to system pressure as indicated by chamber

pressure gauges.

11. The Moisture Indicator's (if dryer so-equipped) bleed

valve is installed directly into the back of the

indicator's body. Close the Indicator's Bleed Valve.

FULLY open the Moisture Indicator Supply Valve.

12. Soap bubble test all external piping, fittings, and con-

nections. Locate and repair all noted points of leak-

age. Do not soap bubble test components lo-

cated inside dryer control system's enclosure.

Note: Small leaks noted in inlet piping to the dryer

will not affect operation, other than a slight loss of

pressure supplied to the dryer. HOWEVER, any gas

3.1

Start-Up

WARNING!

Ensure that the dryer is de-energized, valve isolated

and fully depressurized before attempting to remove

or disassemble any dryer component or subassembly.

Failure to do so may result in serious personal injury

and/or equipment damage.

CAUTION: Each component of a General Pneumatics

Regenerative Desiccant Dryer System has been selected

to compliment the performance of the other components of

the system. Therefore, use of unauthorized parts or sup-

plies or improper operation will degrade system perfor-

mance.

Note: All filter assemblies are shipped WITH filter car-

tridges installed. Prefilter and Afterfilter Cartridges are

NOT interchangeable and must be installed in their respec-

tive assemblies ONLY. The proper filter cartridge part

number is listed on each prefilter and afterfilter assembly.

Dryer Models OP15 through OP200

1.

Close any manual vent or drain valves installed in

prefilter and afterfilter assemblies.

2.

If the prefilter assembly was factory equipped with an

automatic drain valve or drain trap, inspect for, and

remove pipe plug or cap which may have been in-

stalled in drain port for shipping purposes.

3.

Ensure that all associated pipe and tubing connec-

tions, flanges, unions, plugs, mounting bolts, pipe

hangers, etc., have been checked tight and/or prop-

erly secured.

IMPORTANT: It is recommended that the System's

process gas output not be consumed or used at the

intended points of use until the Start-Up and any re-

lated adjustments have been completed, and the sys-

tem is producing process gas of the required quality.

The quality of the process gas should be verified