Maintenance and Repair

4 - 27

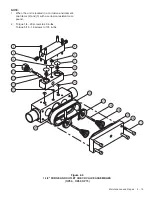

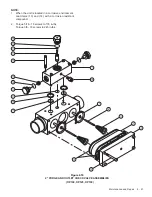

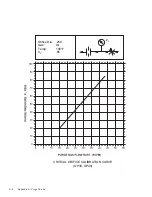

SHAFT SUBASSEMBLY

Item

Description

Total

2B1

Poppet Shaft

1

2B2

Orifice Plate

1

2B3

Orifice Spring

1

2B4

Washer

1

2B5

Slotted Nut

1

2B6

Cotter Pin

1

SHAFT SUBASSEMBLY

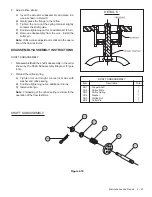

DETAIL 'C'

2.

Adjust orifice stroke.

A) Invert the actuator subassembly and place in a

vice as shown in Detail C.

B) Gently press the flange to the orifice.

C) Tighten the nut until the spring retainer slightly

contacts the shaft guide.

D) Continue tightening nut for an additional 1/2 turn.

E) Remove subassembly from the vice. Install the

cotter pin.

Note: Orifice stroke adjustment is critical to the opera-

tion of the flow restrictor.

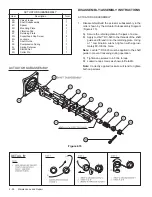

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

SHAFT SUBASSEMBLY

1.

Disassemble/Build the shaft subassembly in the order

shown by the Shaft Subassembly Diagram (Figure

4.16).

2.

Preload the orifice spring.

A) Tighten nut until slight contact is made with

washer and orifice spring.

B) Continue tightening nut an additional 3 turns.

C) Install cotter pin.

Note: Preloading of the orifice spring is critical to the

operation of the flow restrictor.

Figure 4.16