90VDC motor, or “J” for a 230VAC input and 180VDC motor.

2. Output Wiring

a. Connect the motor to the “A1” and “A2” terminals of the drive. Do not operate the control without connection to the motor.

b. Install a jumper for armature voltage feedback at position “I”.

3. Control Wiring

a. Speed potentiometer - For unidirectional rotation, connect a 5K, 1/4 watt speed potentiometer, with the wiper connected to

terminal “8” and CCW end to terminal “3”. Connect the other end to terminal “1”. For bi-directional rotation, connect the CCW

end to terminal “2”.

b. If an external speed reference signal is used, first set-up and adjust the system with a 5K potentiometer as a speed reference.

Connect the

external source only after satisfactory operation with a potentiometer, as any problem may then be directed toward

interfacing. The frequency of a pulse width modulated input signal must exceed 50Hz, otherwise damage may result.

An external signal of 0 to positive 6VDC is used for forward motion. A zero to -6VDC signal is required for reverse motion.

Wire common to terminal “3” and reference signal to terminal “8”.

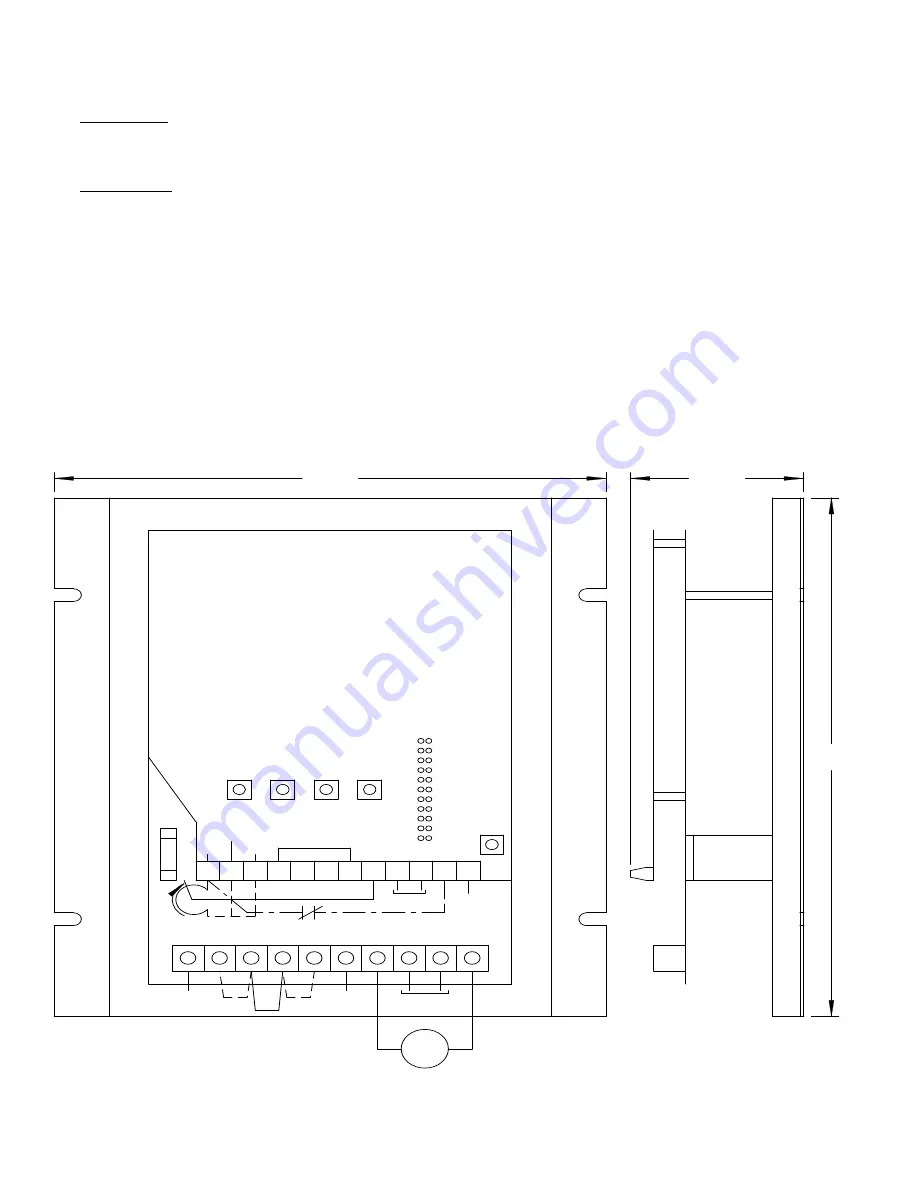

Wiring Diagram and Model 12M6-42000

DEAD

BAND

8.00"

12

11

10

9

8

7

6

5

4

3

2

1

L1

H1

H3

H2

H4

L2

A2

S1

S2

A1

COM

-6V

+6V

7.00"

3.50"

STABILITY

CURRENT

LIMIT

MAX

SPEED

IR

COMP

JUMPERS

K

J

I

H

G

F

E

D

C

B

A

FUSE

TACH FB

INHIBIT

AC LINE

120V

120V

240V

MOTOR

AC LINE

FACTORY

JUMPER

90V

180V

VOLT FB

TACH FB

115V

75V

50V

35V

22V

15V

10V