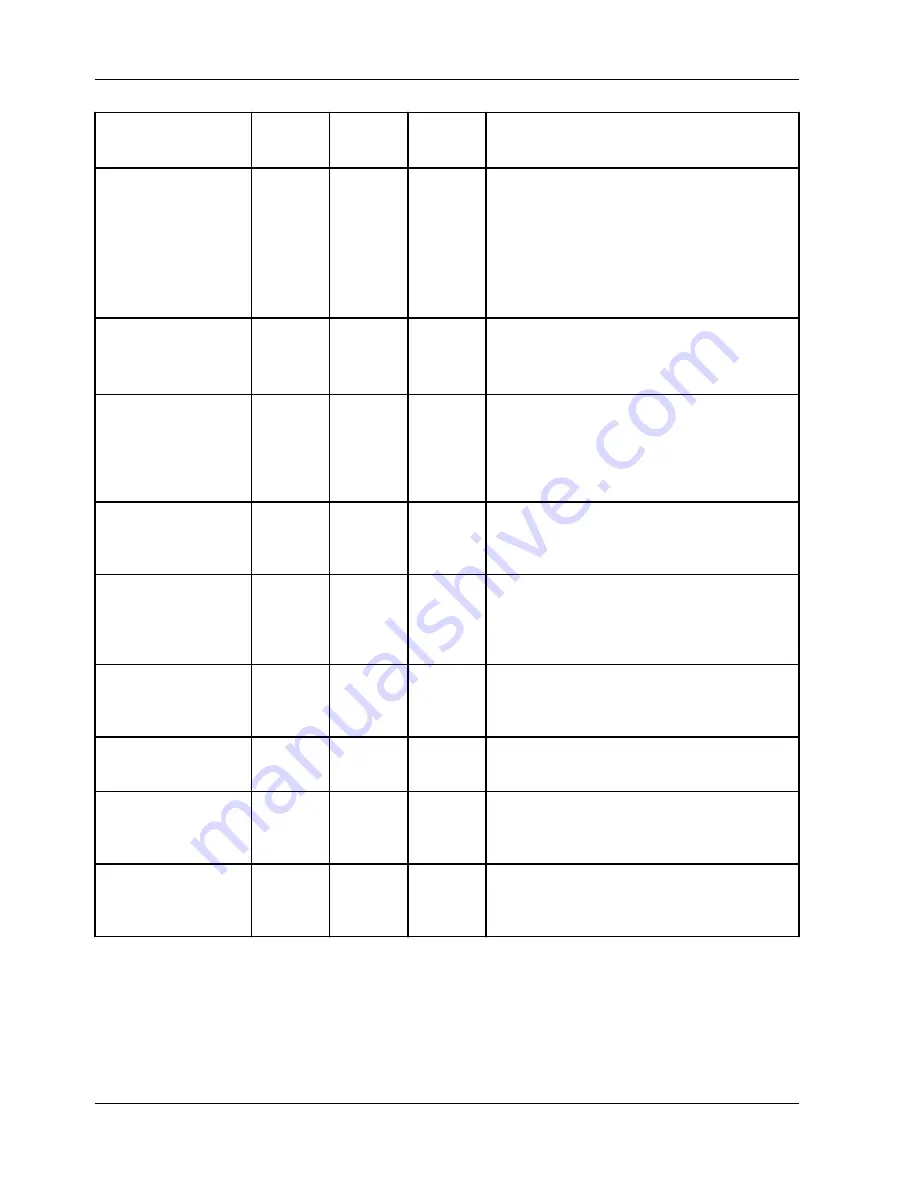

Parameter to be

checked

Every 24

to 72hrs

Weekly

Monthly

Remark

Discharge temperature

X

Minimum superheat must not be less than 15 K

for NH

3

. For other refrigerants, the manufactur-

er's instructions must be noted.

Maximum discharge temperature 100°C, in indi-

vidual cases (e.g. heat pump applications) this

may be exceeded in agreement with the manu-

facturer.

Oil temperature

X

See parameter list!

The viscosity must not be less than 7 cSt at

max. speed (rpm).

Oil pressure

X

The oil pressure must be at least 0.5 bar above

the final discharge pressure. An oil pressure

fault may be caused by a clogged oil filter. Set-

ting and monitoring of the values in accordance

with the information in the parameter list.

Discharge pressure

X

See project value (parameter list). Determine

the superheat on the pressure side by compari-

son with the final discharge temperature.

Oil level in oil separa-

tor

X

See chapter "Oil level check". An oil level must

be visible in the sight glasses at all times. If the

oil level is below the minimum value, the oil

must be recharged.

Oil heater

X

When compressor is shut down, the heater

must automatically start. Visual check, the

green LED indicates "Voltage ON".

Setting the safety devi-

ces

X

See set values in the parameter list.

Capacity control

X

Solenoid valves must switch audibly when the

capacity is adjusted. Check in operating mode

"1 ( manual)“.

Number of operating

hours

X

See maintenance checklist for maintenance

work to be carried out according to the number

of operating hours.

10.4.4.21

Maintenance of the switching

cabinet

Terminal screws must be checked for tightness and,

if necessary, tightened at regular intervals (every

5,000 operating hours or at least once per year). The

Cleaning, maintenance, repair

Operating Manual | GEA Grasso M-Series

Screw Compressor Packages

82

GEA Refrigeration Germany GmbH | P_261511_1 | Generated 01.04.2015

Summary of Contents for Grasso M-Series

Page 88: ......