11

Alarms

11.1

Malfunctions and remedies

Notice!

Warning of damage to property/loss of product

Ignoring malfunctions may cause considerable damage to property and loss

of product. The safe operation of the valve in the event of a fault can no

longer be taken for granted and in the worst case can result in a loss of

sterility in the process.

► Make sure that malfunctions are quickly identified and promptly fixed.

In the event of malfunctions immediately deactivate the valve and secure it

against inadvertent reactivation. Malfunctions may only be remedied by qualified

staff, who must observe the safety instructions. For malfunctions not listed in the

table below, contact the manufacturer.

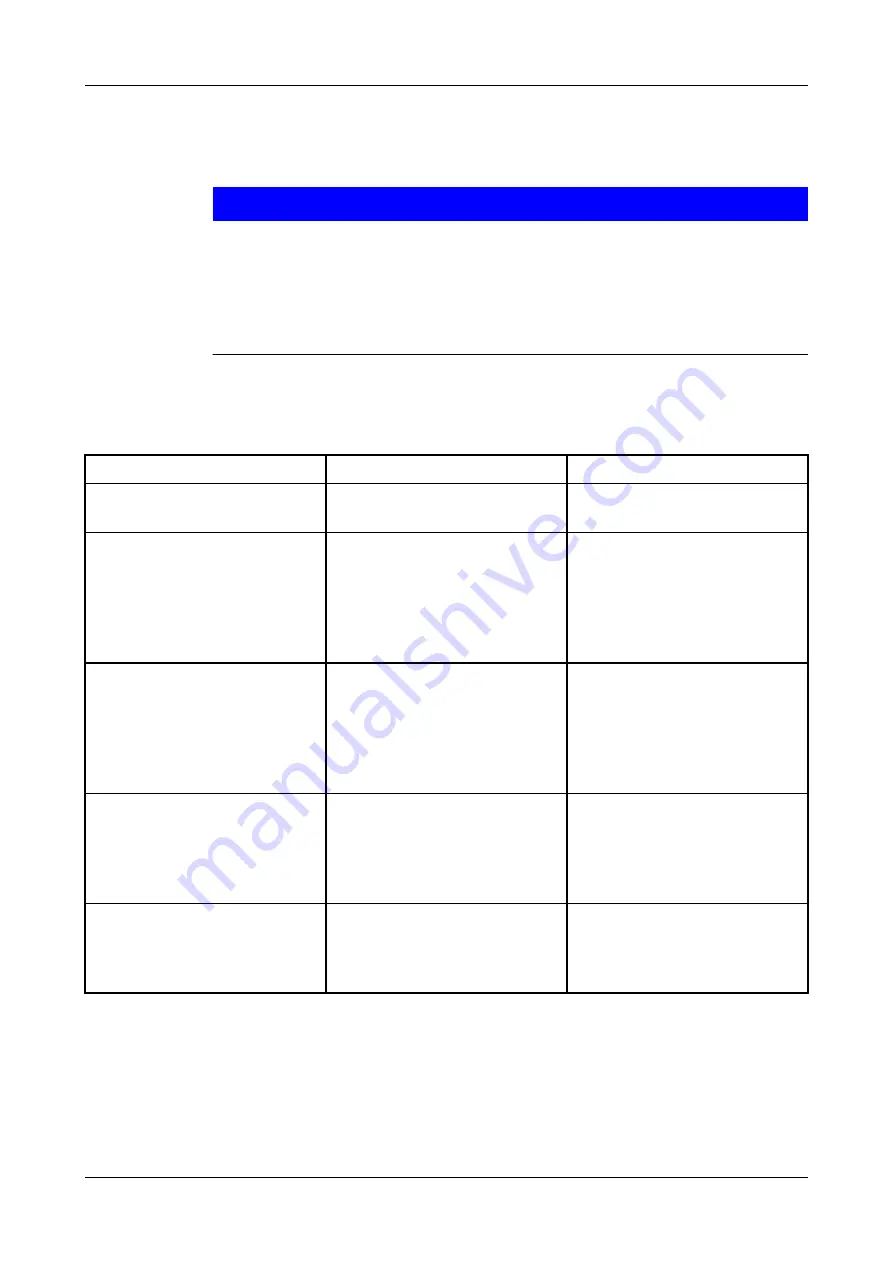

Malfunction

Cause

Remedy

Medium is leaking from the

clamp.

The housing seal is not fitted

correctly or damaged.

Fit the housing seal correctly

or replace it if damaged.

Medium is leaking from the

leakage holes of the internal

assembly.

The metal bellows on the

internal assembly is defective.

•

Replace the complete

internal assembly.

•

Send the defective internal

assembly to the

manufacturer for repair.

During pressure testing of the

internal assembly, air escapes

from the metal bellows.

The metal bellows on the

internal assembly is defective.

•

Replace the complete

internal assembly.

•

Send the defective internal

assembly to the

manufacturer for repair.

Leak at the valve seat.

•

The valve seat seal is

defective.

•

Product deposits on the

valve seat.

•

Replace the valve seat

seal.

•

Check the housing.

The maximum valve stroke is

not reached when the valve is

actuated pneumatically.

Leakage in the actuator.

•

Check the sealing surfaces

in the actuator for damage.

•

Replace the seals.

Alarms

Malfunctions and remedies

430BAL012727EN_1

60

03.01.2018

Summary of Contents for Aseptomag GD

Page 65: ...Appendix 430BAL012727EN_1 03 01 2018 65...

Page 66: ......