Stránka

18

z

39

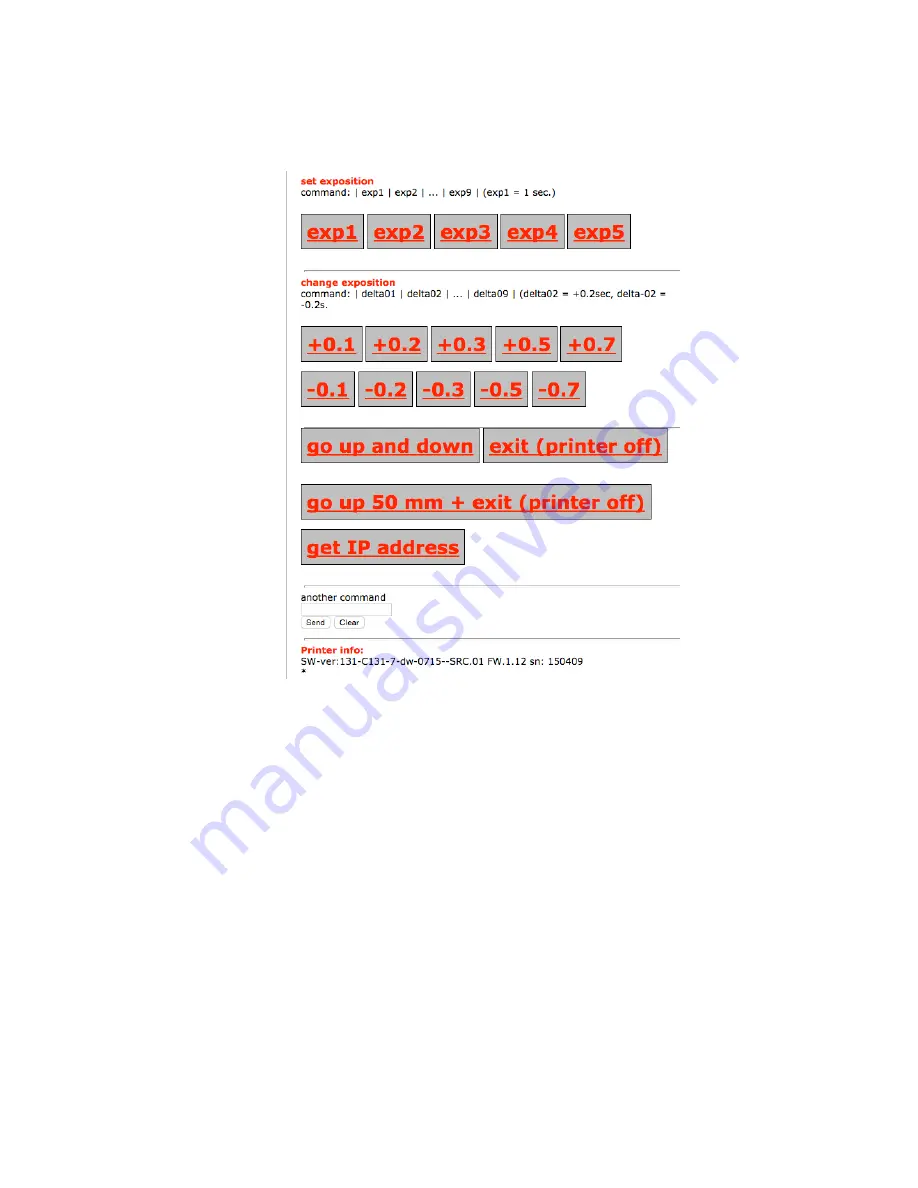

Home-‐command

In this part of menu, you can change the exposition times of individual layers during the

print.

exp1

= exposition time of each layer = 1 s

You can change the exposition time in steps of one tenth of a second.

+0,1 s

-‐0,1 s

GO UP AND DOWN

– You can lift and than lower the platform – used for checking the

progress during the print.

EXIT

– turning off the printer fast

GO UP 50 mm + exit

– Platform is lifted by 50 mm and afterwards the printer is turned off.

Used when you find out that the setting was wrong or there is another problem and

therefore you want to turn off the printer and repeat the print with different settings.