2-1

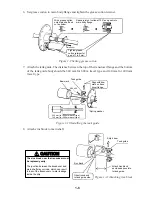

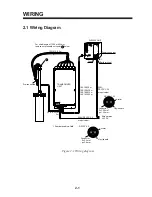

WIRING

2.1 Wiring Diagram

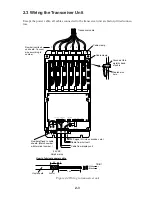

3

5

2

4

6

1

-

+

SCREEN FOCUS

*1

Power connector

Earth terminal

Fuse

Pre-connected

VV-S 0.5x10C

3 m

10S1915, 6.6 m

10S1903,5 m

10S1904,10 m

10S1905,15 m

10S1925,30 m

250V-DPYCY-3.5

or equivalent

250V-

DPYCY-1.25

or equivalent

Ship’s mains

24 VDC

TRANSCEIVER

UNIT

DISPLAY UNIT

*1

*1 Fabricate cable in field.

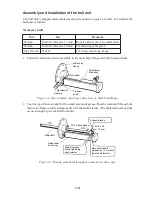

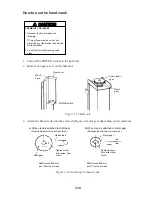

For shaft length of 1300 or 945 mm,

remove outer sheath until point a below.

a

,

,

,

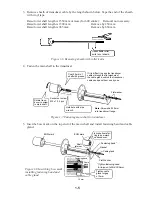

DPYCY-1.25

Armar

Vinyl sheath

Conductor

S=1.25 mm

2

φ

=1.35 mm

,

,

DPYCY-3.5

Armar

Vinyl sheath

Conductor

S=3.5 mm

2

φ

=2.4 mm

Figure 2-1 Wiring diagram

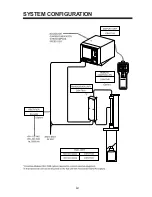

Summary of Contents for CSH-7

Page 1: ...COLOR SCANNING SONAR MODEL CSH 7 ...

Page 4: ...ii ...

Page 6: ...iv SYSTEM CONFIGURATION ...

Page 15: ...1 8 ...

Page 16: ...1 9 ...

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......