1-6

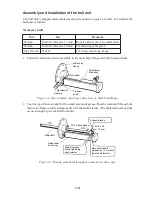

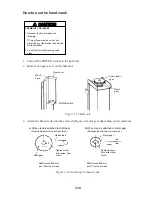

6. Set grease cotton to main body flange and tighten the grease cotton retainer.

Wind grease cotton

onto main shaft and

cut as below.

Space joints of cotton at 120

°

and push into

main body flange.

Tighten grease

cotton retainer for

gap of 7 to 9 mm.

Flat washer

Figure 1-9 Setting grease cotton

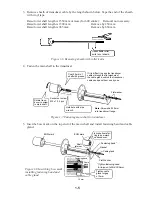

7. Attach the tank guide. The distance between the top of the transducer flange and the bottom

of the tank guide body should be 340 mm for 600 m travel type and 140 mm for 400 mm

travel type.

Bow mark

Tank guide

Align with bow

mark on trans-

ducer flange.

340 mm (for 600 mm travel type)

140 mm (for 400 mm travel type)

M10 x 55

M10 SW*

* Spring washer

Figure 1-10 Installing the tank guide

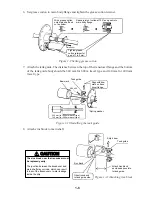

8. Attach zinc block to main shaft..

CAUTION

The zinc block near the transducer must

be replaced yearly.

The junction between the transducer and

main shaft may corrode, which can result

in loss of the transducer or water leakage

inside the ship.

Ship's bow

Tank guide

Zinc block

Orient round end

to tank guide side.

Attach zinc block

as close as possible

to tank guide.

Figure 1-11 Attaching zinc block

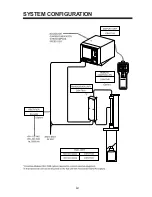

Summary of Contents for CSH-7

Page 1: ...COLOR SCANNING SONAR MODEL CSH 7 ...

Page 4: ...ii ...

Page 6: ...iv SYSTEM CONFIGURATION ...

Page 15: ...1 8 ...

Page 16: ...1 9 ...

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......