2-3-3

U25PALMA

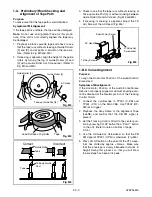

1-A. Preliminary/Final Checking and

Alignment of Tape Path

Purpose:

To make sure that the tape path is well stabilized.

Symptom of Misalignment:

If the tape path is unstable, the tape will be damaged.

Note:

Do not use an Alignment Tape for this proce-

dure. If the unit is not correctly aligned, the tape may

be damaged.

1. Playback a blank cassette tape and check to see

that the tape runs without creasing at Guide Rollers

[2] and [3], and at points A and B on the lead sur-

face. (Refer to Fig M3 and M4.)

2. If creasing is apparent, align the height of the guide

rollers by turning the top of Guide Rollers [2] and

[3] with a Guide Roller Adj. Screwdriver. (Refer to

Fig. M3 and M5.)

3. Check to see that the tape runs without creasing at

Take-up Guide Post [4] or without snaking between

Guide Roller [3] and AC Head. (Fig. M3 and M5)

4. If creasing or snaking is apparent, adjust the Tilt

Adj. Screw of the AC Head. (Fig. M6)

1-B. X Value Alignment

Purpose:

To align the Horizontal Position of the Audio/Control/

Erase Head.

Symptom of Misalignment:

If the Horizontal Position of the Audio/Control/Erase

Head is not properly aligned, maximum envelope can-

not be obtained at the Neutral position of the Tracking

Control Circuit.

1. Connect the oscilloscope to TP301 (C-PB) and

TP501 (CTL) on the Main CBA. Use TP502 (RF-

SW) as a trigger.

2. Playback the Gray Scale of the Alignment Tape

(FL6N8) and confirm that the PB FM signal is

present.

3. Set the Tracking Control Circuit to the center posi-

tion by pressing CH UP button then “ PLAY ” button

on the unit. (Refer to note on bottom of page

2-3-4.)

4. Use the X-Value Adj. Screwdriver so that the PB

FM signal at TP301 (C-PB) is maximum. (Fig. M6)

5. Press CH UP button on the unit until the CTL wave-

form has shifted by approx. +2msec. Make sure

that the envelope is simply attenuated (shrinks in

height) during this process so that you will know

the envelope has been at its peak.

Guide Roller [2]

Guide Roller [3]

A

B

Take-up Guide Post [4]

AC Head

Fig. M3

Lead Surface of Cylinder

Tape

Fig. M4

Guide Roller

Tape

Correct

Incorrect

Take-up Guide

Post

Tape

Fig. M5

Azimuth Adj. Screw

X-Value Adj.

Screwdriver

Tilt Adj. Screw

AC Head

Fig. M6

Summary of Contents for 25A-664

Page 22: ...1 8 3 1 8 4 1 8 5 HC4S4SCM1 Main 1 5 Schematic Diagram ...

Page 23: ...1 8 6 1 8 7 1 8 8 HC4S4SCM2 Main 2 5 Schematic Diagram ...

Page 24: ...1 8 9 1 8 10 1 8 11 HC4S4SCM3 Main 3 5 Schematic Diagram ...

Page 26: ...Main 5 5 Schematic Diagram 1 8 15 1 8 16 HC4S4SCM5 ...

Page 27: ...VPS Schematic Diagram 1 8 17 1 8 18 HC4S4SCV ...

Page 28: ...1 8 19 1 8 20 HC4S4SCF Function Schematic Diagram ...

Page 29: ...AFV Schematic Diagram 1 8 21 1 8 22 HC4S4SCAFV ...

Page 30: ...Jack Schematic Diagram 1 8 23 1 8 24 HC4S4SCJ ...

Page 31: ...1 8 25 1 8 26 Function CBA Top View Function CBA Bottom View BHC400F01018 B ...

Page 33: ...1 8 29 1 8 30 Jack CBA Top View Jack CBA Bottom View BHC400F01018 E ...

Page 54: ...2 4 6 U25PALDA S 12 19 Cap Belt Fig DM11 Fig DM12 20 C 1 21 ...

Page 60: ...3 1 1 HC4C0FEX A1X EXPLODED VIEWS Front Panel ...

Page 81: ...25A 664 HC4S4ED ...