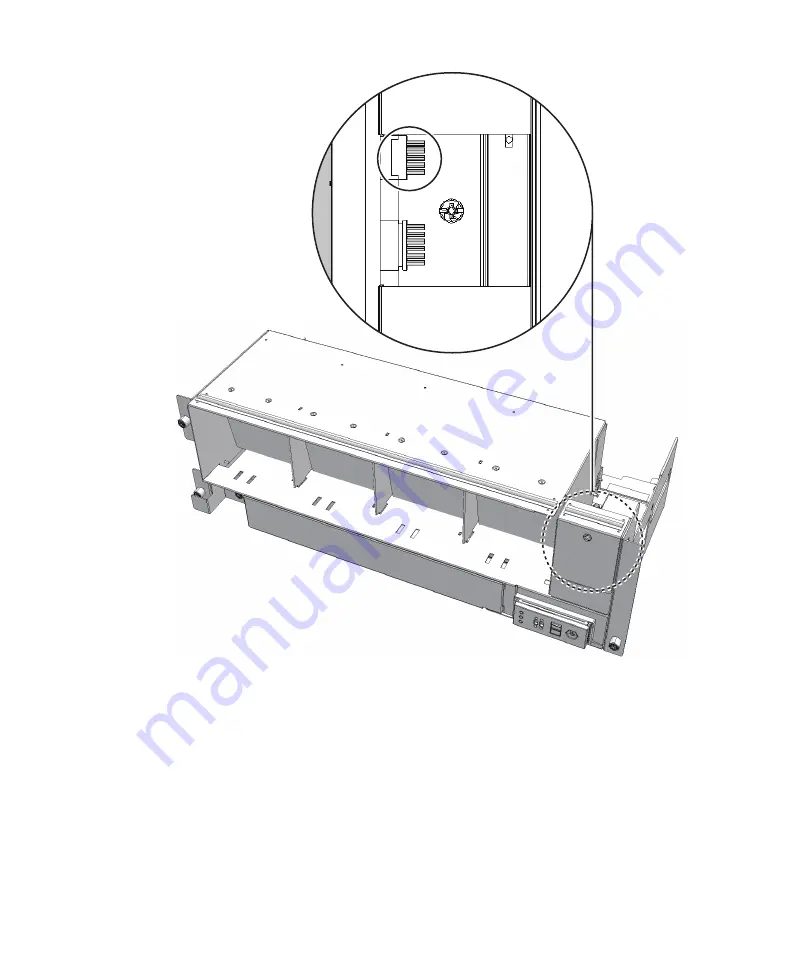

Front

Figure

23-9

Operation

panel

cable

23.5.2

Restoring

the

chassis

1.

Support

the

fan

shelf

from

below

with

one

hand

and

insert

it

into

the

chassis.

Then,

tighten

the

three

screws.

2.

Connect

the

two

cables

to

the

fan

shelf.

3.

Install

the

lower

cover

and

then

secure

it

with

the

one

screw

.

4.

Install

the

upper

cover

and

slide

the

right

and

left

stoppers

outwards.

Then,

tighten

the

two

screws

to

secure

the

upper

cover.

5.

Install

all

the

fan

units.

Fujitsu

M10-4/Fujitsu

M10-4S/SPARC

M10-4/SPARC

M10-4S

Service

Manual

・

February

2014

368

Summary of Contents for SPARC M10-4

Page 20: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 xx ...

Page 34: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 10 ...

Page 56: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 32 ...

Page 94: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 70 ...

Page 110: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 86 ...

Page 264: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 240 ...

Page 290: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 266 ...

Page 306: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 282 ...

Page 328: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 304 ...

Page 338: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 314 ...

Page 382: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 358 ...

Page 394: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 370 ...

Page 416: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 392 ...

Page 440: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 416 ...

Page 468: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 444 ...

Page 480: ...Fujitsu M10 4 Fujitsu M10 4S SPARC M10 4 SPARC M10 4S Service Manual February 2014 456 ...