218

Upgrade and Maintenance Manual

TX1310

M1

Cables

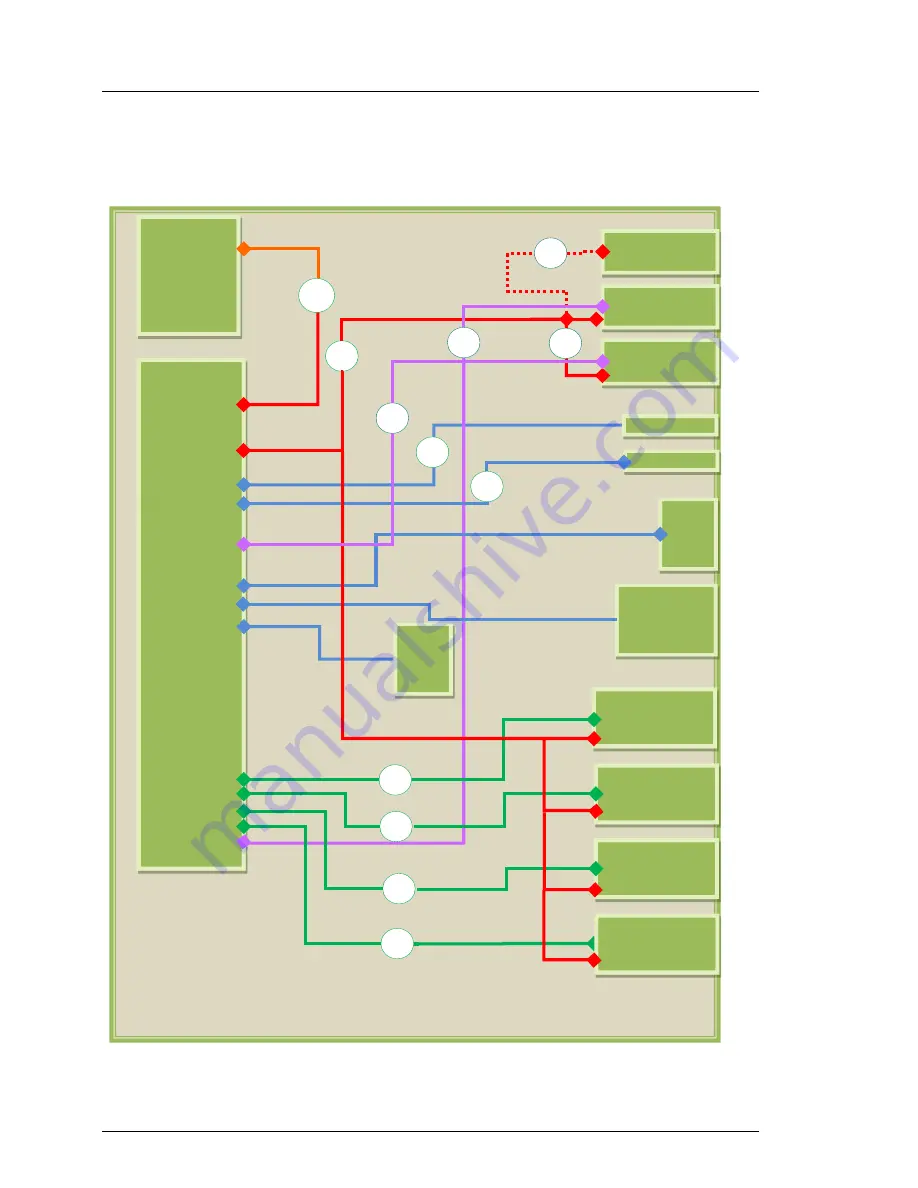

15.2 Cabling plans

Figure 159: Power distribution for system board

HDD

extension

Fan

- D3219

Power Supply

250W

-E563-V50

PWR1 ---------------

C10

C2

C20

PWR2 ---------------

SATA HDD 1

C22

Front

Fan

C12

Access. Bay 1

ODD/DVD

Access. Bay 2

Backup Drive

Front Panel

2x USB 3.0

SATA HDD 2

SATA HDD 3

SATA HDD 4

CPU

Fan

SATA 1 --------------

SATA 2 --------------

SATA 3 --------------

SATA 4 --------------

SATA 5 --------------

SATA 6 --------------

FAN1 SYS ----------

FAN2 SYS ----------

FAN CPU ----------

FRONT PANEL ---

USB FRONT ---------

C1

C21

C22

C21

USB 1 - --------------

C26

C4

Access. Bay 1

Slimline ODD

C3

Summary of Contents for PRIMERGY TX1310 M1

Page 6: ...Upgrade and Maintenance Manual TX1310 M1 Version history ...

Page 18: ...18 Upgrade and Maintenance Manual TX1310 M1 Introduction ...

Page 38: ...38 Upgrade and Maintenance Manual TX1310 M1 Important information ...

Page 132: ...132 Upgrade and Maintenance Manual TX1310 M1 Expansion cards and backup units ...

Page 220: ...220 Upgrade and Maintenance Manual TX1310 M1 Cables ...