Instruction Manual

Fuji Electric Co.,Ltd.

INZ-TN1ZRFb-E

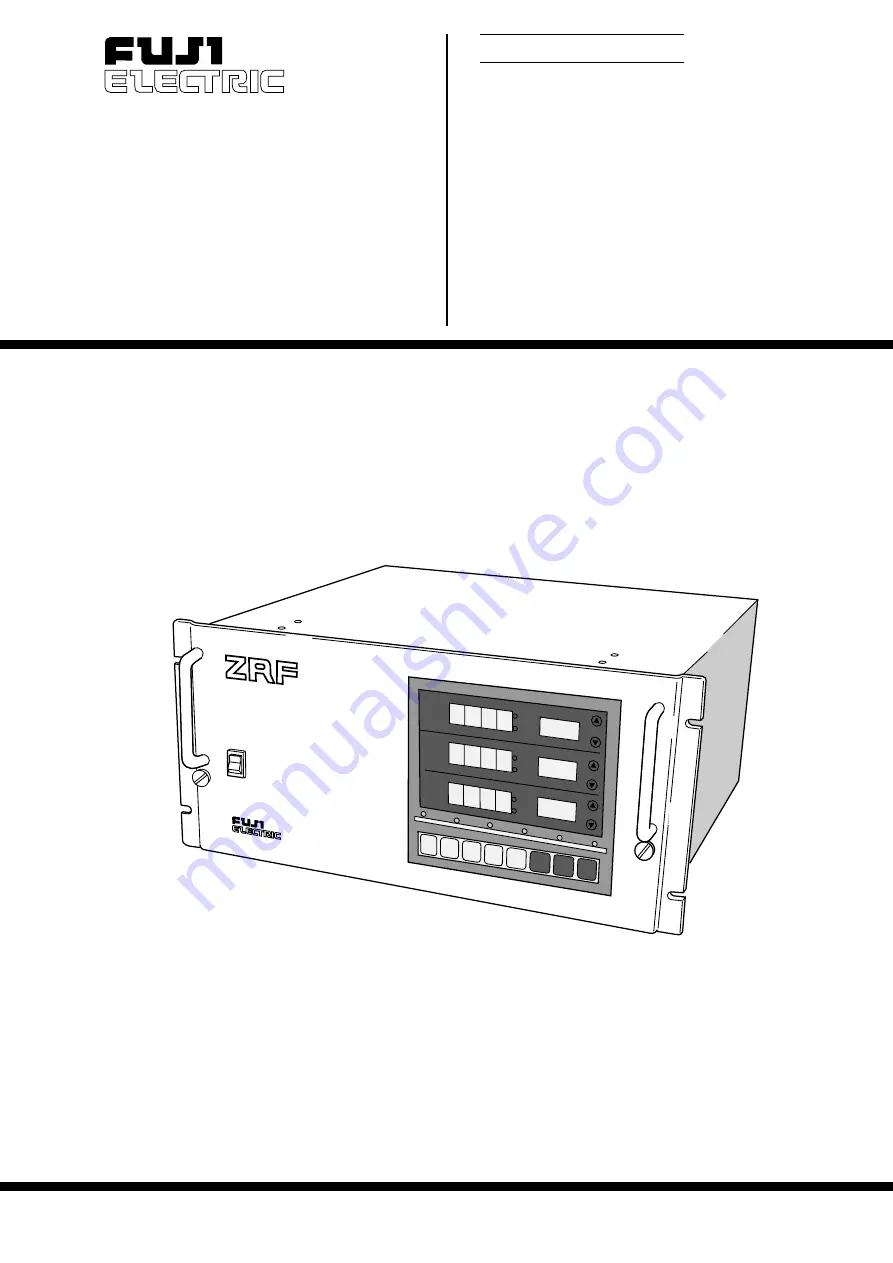

NON-DISPERSION TYPE

INFRARED GAS ANALYZER

TYPE: ZRF

INFRARED GAS AN

ALYZER

NO

vol%

ppm

vol%

ppm

RANGE

RANGE

AUTO CAL

HOLD

SPAN

CAL

SPAN

ZERO

ENT

COMP

FUNC

∧

>

MEAS

MEAS

RMT RANGE

SO

2

vol%

ppm

RANGE

O

2

POWER

ON

OFF