8 Periodic inspection and cleaning

The electrostatic precipitator system must be inspected and cleaned at appropriate

intervals depending on the operating hours and fuel quality.

Inspection and cleaning must be repeated after not more than 1000 operating hours or

at least every six months. For less efficient fuels (e.g. high ash content) this work

needs to be carried out more frequently.

Thorough cleaning of the entire electrostatic precipitator system and the boiler must

be carried out immediately prior to emissions measurement.

8.1 Cleaning electrodes and the interior

Carry out the following cleaning work on all modules of the electrostatic precipitator

system.

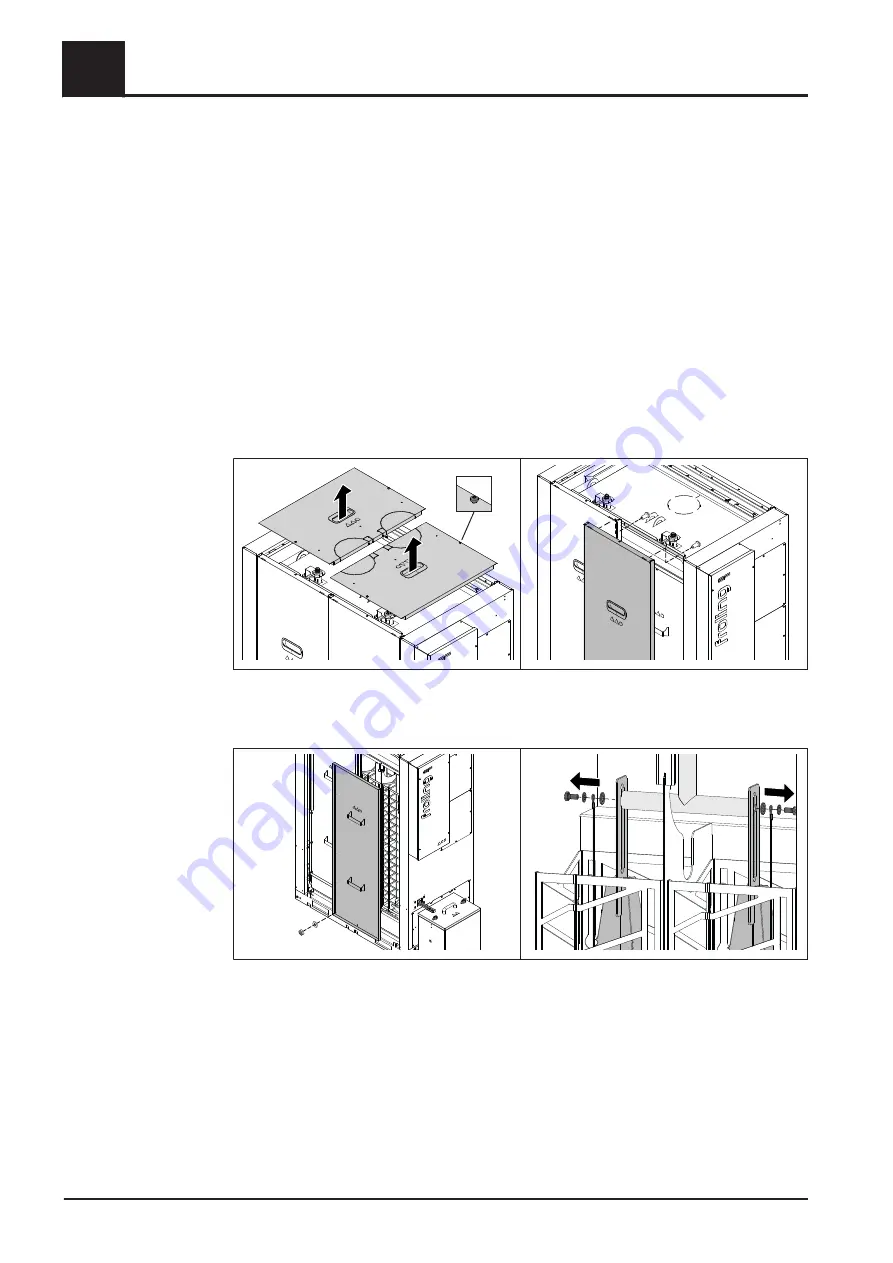

❒ Loosen screws and remove the top cover

❒ Loosen the upper screws and unhook the side panels

❒ Remove maintenance cover

❒ Loosen screws on the insulator and remove the high-voltage cable

IMPORTANT: When fitting the maintenance covers, use the previously removed brass

nuts! If nuts are lost or can no longer be fitted due to wear, replacement nuts must be

ordered from Froling GesmbH (Art. No. T206173).

8

Periodic inspection and cleaning

Cleaning electrodes and the interior

38

Fröling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com