2638A

Users Manual

1-6

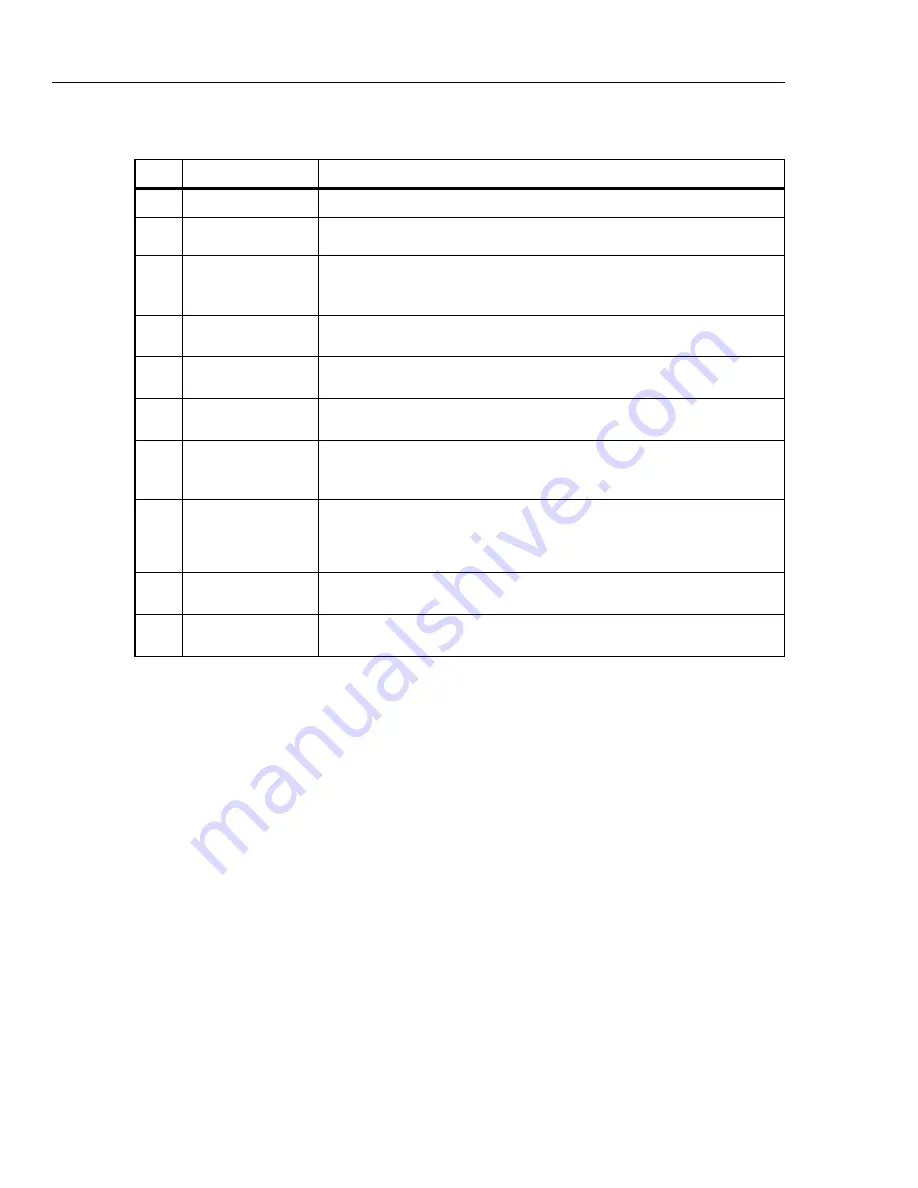

Table 1-2. Rear-Panel Features (cont.)

Item Name

Function

Main Power Switch

Supplies and disconnects mains power to the unit.

Mains Power

Connector

Mains power cord receptacle.

Chassis Ground

Terminal that is internally grounded to the chassis. If the Product is the

location of the ground reference point in a system, this binding post can be

used to connect other instruments to earth ground.

Serial USB Port

USB port used for remote operation. See the

2638A Remote Programmers

Guide

.

LAN Connection

Network port used for remote operation. See the

2638A Remote

Programmers Guide

.

Totalizer Input

Input terminal for the Totalizer feature. See “Totalizer Channel

Configuration” in Chapter 3.

DIO (Digital I/O

Input Ports)

Eight digital ports used to sense and output a digital, 8-bit transistor-

transistor logic (TTL) value that can be displayed as the 8-bit TTL value and

be recorded as the decimal equivalent.

Digital External

Alarm Trigger

Outputs

Six digital outputs that can be used to trigger a digital external alarm if a

channel exceeds the set alarm limits. See “HI and LO Channel Alarms” in

Chapter 3.

Trigger

Input

Input terminal to trigger a scan when the External trigger type is used. See

Scan Test Setup” in Chapter 4.

Input Module Slots

Slots that accept the Input Modules. See “Input Module and Relay Card

Installation” in Chapter 2. The 2638A/05 has only one usable slot.

1.888.475.5235

Fluke-Direct

.com