FAD-40 Technical Manual, Rev.2.1.0; February 2022

Page 34 of 55

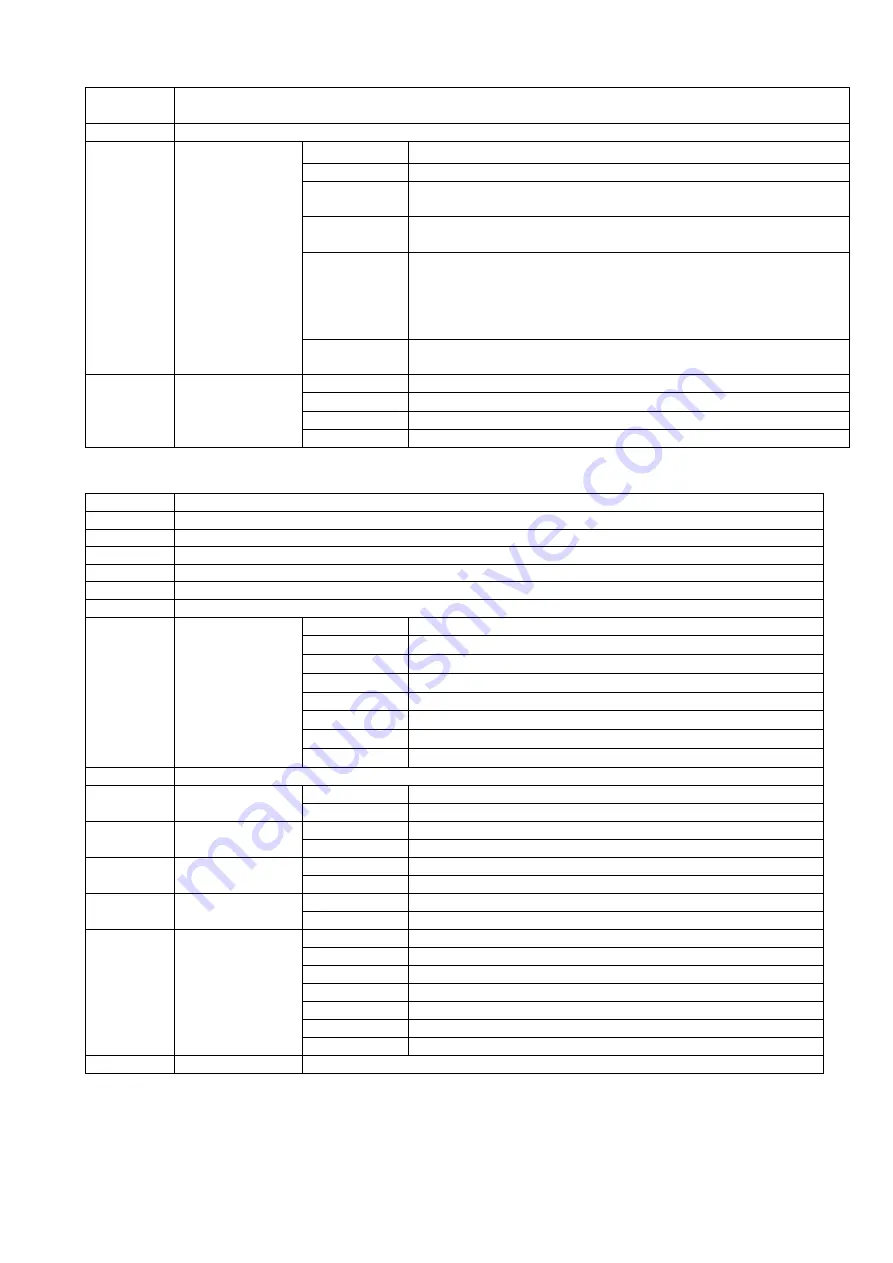

Calibration Status

Bit no.

2

nd

Dword descriptions when read command is ‘Calibration Status’.

Refer to PLC Output to FAD-40Px Input 3

rd

Dword

D31…D16 Not in use

D15…D8

Calibration

error

0000 0001

Calibration timeout: - Restart calibration

0000 0010

ADC error: - Re-energize the instrument

0000 0011

Instrument cannot be calibrated

- Check load cell cable; - Re-energize the instrument

0010 0010

Instrument cannot be calibrated

- Load cell signal is very low or too high

0010 0011

Calibration Error

- Calibration test weight is too small; Increase calibration weight

value (Write test weight value from PLC Output to FAD-30Px

Input 2

nd

Dword then restart the calibration)

- Check load cell connections

0010 0101

Scale unstable: - Wait until scale becomes stable

- Check ground wiring

D7...D0

Calibration

process

status

0000 0001

System ready for calibration

0000 0011

Zero calibration in process

0000 0100

Span calibration in process

0000 1001

Error (Calibration error)

FAD-40Px Output to PLC Input 3

rd

Dword

Bit no.

3

rd

Dword Description

D31…D21 Not in use

D20

Input for I/O2

D19

Input for I/O3

D18

Output for I/O3

D17

Output for I/O2

D16

Output for I/O1

D15…D12

Error codes of

converter

0000

No error found

0001

ADC out

0010

ADC over

0011

ADC under

0100

System error

0101

In setup mode

0110

Low/High voltage error

0111

Instrument not found

D11…D10 Not in use

D9

Operation mode

0

Weight & Force Mode

1

Count Mode

D8

Zero range

0

Weight is out of zero range

1

Weight is in of zero range

D7

Indication

0

Gross

1

Net

D6

MD

–

Motion detection

0

Stable

1

Unstable

D5

D4

D3

D2

D1

Read command

response

00000

Indicated weight

00001

Gross weight

00010

Tare weight

00011

Indicated weight (floating point type)

00100

Gross weight (floating point type)

00101

Tare weight (floating point type)

10000

Calibration Status (Refer to table 8.2)

D0

CMD flag

A change of Flag indicates: The command is applied successfully