25

ZAPEX 3502 en

Operating instructions 10/2017

The coupling parts (1/2) should be pushed smartly onto the shaft up to the position specified in the

orderspecific dimensioned drawing.

The coupling parts (1/2) must be held in position on the shaft with the aid of a suitable retaining

device, until they cool down and seat firmly.

After the coupling parts (1/2) have cooled down to ambient temperature the oil channels must be filled with

clean forcing oil, e.g. ISO VG 150, and resealed with the screw plugs (22) (rust protection).

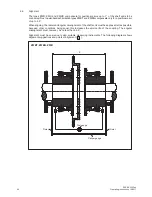

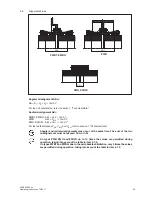

6.5

Fitting the coupling

Oil the teeth of the coupling parts (1/2) and of the flanged sleeves (5) and/or the coupling sleeve (5) and

the hub circumferences of the parts (1/2) (sealing surfaces).

Push the flanged sleeves (5) onto the teeth of the coupling parts (1/2) and hold and/or brace them in

position. In case of types ZWH and ZWHD, push the coupling sleeve (5) onto the teeth of a coupling

part (1/2) and hold and/or brace them in position. In case of types ZWBT and ZWBG place the

axialbacklash limiting device (52) into the recess of part 1 and pull the flanged sleeve (5) over the in die

axialbacklash limiting device (52). In case of types ZWBT, ZWBG and ZWB place the brake disk (13)

between the two flanged sleeves (5) hold in position.

Move together the machines to be coupled. The dimensions S

1

to S

15

(see section 1, "Technical data")

are to be observed. Align the coupling as described in items 6.6 to 6.8.

In case of types ZWH and ZWHD, push the coupling sleeve (5) onto the teeth of both coupling parts (1/2).

Using suitable tools, pull the covers (10 and/or 21) onto the hub.

Smear the sealing surfaces of the cover(s) (10 and/or 21) with sealing compound (always apply sealing

compound to one side only) and screw together with the flanged sleeves (5) and/or coupling sleeve (5) (for

tightening torques, see item 6.9).

In case of types ZWBT, ZWBG and ZWB smear the sealing surfaces of the flanged sleeves (5) and/or the

brake disk (13) with sealing compound. Align the fitting holes of the flanges, noting any marks. Insert

closefitting bolts (8) and tighten the nuts (9) (for tightening torques, see item 6.9).

Summary of Contents for Zapex ZWB

Page 2: ......