35

ZAPEX 3502 en

Operating instructions 10/2017

10.

Maintenance and repair

Observe the instructions in section 3, "Safety instructions"!

If a dimensioned drawing has been made out for the coupling, the data in this drawing

must be given priority.

10.1

General

The coupling must be checked for leaks and heating, and any change in the noise level, at general

maintenance intervals or at least every three months.

The coupling must run with little noise and without vibration in all operating phases. Irregular behaviour

must be treated as a fault requiring immediate remedy.

The space required for changing the DUO sealing rings (12) in the cover (10) is given in the dimension

tables in section 1, "Technical data", with letter ”P” and d

6

.

10.2

Oil change and/or grease change

During regular inspections the coupling must be checked for leaks, and the lubricant level checked and,

if necessary, topped up.

Lubricant change approx. every 8000 operating hours or at latest every 2 years in case of operation at up

to 70 °C; in case of operation at over 70 °C approx. every 3000 operating hours or at the latest at yearly

intervals.

10.3

Replacement of wearing parts

Unscrew screw plugs (6) and drain off the oil/grease into a suitable vessel, as shown in the diagram (to

simplify matters, in the case of grease, add lightbodied oil to the used grease and mix).

All the oil and grease must be completely collected and disposed of in accordance

with the regulations applying.

Drainage hole

30°

Ventilation hole

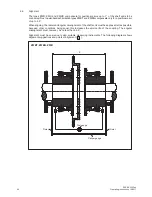

The DUO sealing rings (12) can, if the dimensions d

6

and ”P” are adhered to (see section 1, "Technical

data") without having to detach the coupling, be replaced with openended (cut) DUO sealing rings (12).

For this, undo the cover screw connection (11) and push the cover (10 and/or 21) away from the hub until

the DUO sealing ring (12) can be removed.

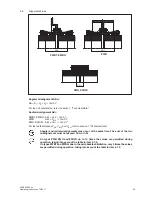

Cut the new DUO sealing ring (12) radially at one point. Before fitting the DUO sealing rings (12), grease

the groove.

DUO sealing rings (12) with trapeziumshaped back section can be fitted without adhesive. For this, place

the cut ends together in the Vshaped groove and then, working outwards from the cut ends, insert the

DUO sealing ring (12) on both sides.

Refit the cover (10 and/or 21) as instructed in section 6, "Assembly". Fill with oil or grease as described

in section 7. "Startup".

Summary of Contents for Zapex ZWB

Page 2: ......