37

ZAPEX 3502 en

Operating instructions 10/2017

Always use suitable lifting equipment!

Danger of squeezing!

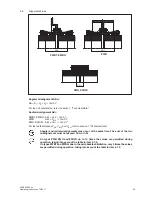

Check the teeth, the seals (12) and the sealing surfaces for damage. Damaged parts must be replaced.

For demounting, the following tools are needed:

•

For each oil channel (for number, see the dimensioned drawing) an oil pump with pressure gauge (min.

2 500 bar) and/or motor pump with corresponding number of independently closable connections

•

Suitable connections and pipes.

•

1 detaching device and/or retaining plate with retaining screws and/or threaded spindles with nuts

(material of screws and spindles min. 10.9, material of nuts identical to that of the screws).

•

1 hydraulic cylinder ("Lukas") with oil pump. Note displacement and pressure of the hydraulic cylinder

(”Lukas”) (for axial force, consult Flender and/or refer to dimensioned drawing).

Observe manufacturer's instructions for using forcingoff/detaching device and

pumps.

Before detaching the coupling hub the detaching device must be fitted as shown in diagrams, illustrations,

etc.

”Lukas”

I

II

IV

III

Retaining plate Threaded spindle

Shaft

22

Using suitable tools, secure coupling parts (1/2) and retaining device!

In case of coupling parts with conical bore, an axial locking must be provided to

prevent the coupling parts from suddenly coming off!

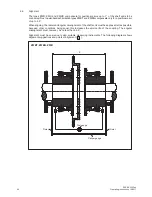

The screw plugs (22) must be removed from the oil channels. An oil pump must be bled and connected

to the middle oil channel (here oil channel I).

Then the pump must be operated at the pressure specified on the dimensioned drawing until oil emerges

from the adjacent connections (oil channels IV and II).

The max. pressure specified on the dimensioned drawing must not be exceeded.

Summary of Contents for Zapex ZWB

Page 2: ......