Instruction Manual

D200319X012

377 Trip Valve

August 2012

4

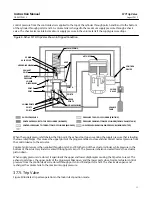

Figure 4. Maximum Trip Point Settings

10.3

4

5

6

7

8

9

10

110

100

90

80

70

60

50

40

7.6

7

6

5

4

3

150

140

130

120

110

100

90

80

70

60

55

NOTES:

TRIP POINT MAY BE SET TO ANY VALUE BETWEEN 2.8 BAR (40 PSIG) AND THE MAXIMUM TRIP POINT LINE.

RESET OCCURS AT 12.5 TO 33 PERCENT ABOVE ADJUSTED TRIP POINT.

TRIP POINT, PSIG

TRIP POINT, BAR

SUPPLY PRESSURE, BAR

SUPPLY PRESSURE, PSIG

A2779‐2/IL

MAXIMUM TRIP POINT

SETTING TO ENSURE

RESET

1

2

2

1

Installation

WARNING

Avoid personal injury from sudden release of process pressure. Before mounting the controller:

D

Always wear protective clothing, gloves, and eyewear when performing any installation operations to avoid personal

injury.

D

Overpressuring any system component could result in personal injury or property damage due to fire and explosion

caused by venting or leakage of the supply medium. To avoid such injury or damage, provide suitable pressure‐relief or

pressure‐limiting devices if the supply pressure is capable of exceeding the maximum allowable pressure of the system

component.

D

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

The 377 trip valve is normally ordered as part of a control valve assembly. Follow the procedure in the appropriate

valve body and actuator instruction manual when installing the control valve in the piping.

If the 377 trip valve is shipped separately from the control valve assembly, the installation procedure depends upon

the type of actuator and accessory equipment required for the individual control valve system. Install any accessory

equipment in the control valve system so that the overall functioning of the specified trip valve pressure line

connections is not disrupted. Figures 7, 8, and 9 are schematics showing the pressure line connections for each of the

three possible fail‐mode configurations of the trip valve.

CAUTION

377 trip valves are leak tested to ensure that the intended actuator fail mode is maintained upon loss of supply pressure.

Control system accessories, such as volume boosters with hard seats, compromise the integrity of the entire system due to