Instruction Manual

D200319X012

377 Trip Valve

August 2012

7

WARNING

If a flammable or hazardous gas is used as the supply pressure medium, personal injury or property damage could result

from fire or explosion of accumulated gas or from contact with hazardous gas. The positioner/ actuator assembly does not

form a gas‐tight seal, and when the assembly is enclosed, a remote vent line, adequate ventilation, and necessary safety

measures should be used. However, a remote vent pipe alone cannot be relied upon to remove all hazardous gas. Vent line

piping should comply with local and regional codes and should be as short as possible with adequate inside diameter and

few bends to reduce case pressure buildup.

Note

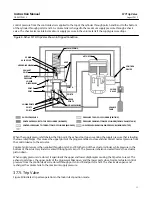

To ensure trip system integrity upon loss of supply pressure, a 377D or 377U trip system requires a volume tank and check valve as

shown in figures 7 and 9.

State and local regulations may require the use of ASME approved volume tanks. Determine requirements and applicable

regulations for proper volume tank selection.

For ASME approved applications, the volume tank is rated at 10.3 bar (150 psig) internal working pressure, and has a safety valve

with a 10.3 bar (150 psig) set pressure mounted on the volume tank for pressure relief. Avoid supply pressure too near the safety

valve set pressure. To ensure safety valve seat tightness and longevity, the recommended maximum supply pressure is 9.3 bar

(135 psig).

Standard volume tanks supplied in Europe must conform to Directive 2009/105/EC for simple pressure vessels. The maximum

pressure rating is stated on the tank.

For standard applications (not ASME approved), a DOT tank is used. This tank is rated at 14.5 bar (240 psig) in LP service. When

used with air, the rating should be considered to be 10.3 bar (150 psig), consistent with the maximum pressure allowed for the

377 trip valve.

1. Before installing the trip valve, inspect it to be sure it is free of any foreign material.

2. Be sure all connecting tubing is free of foreign material.

3. Use acceptable piping practices when installing the trip valve. Coat all external threaded connections with a pipe

compound.

CAUTION

To avoid damage and possible operational impairment to the trip valve, be careful not to get excessive pipe compound on

the connections. Excess compound could result in improper pilot and cylinder valve operation.

CAUTION

To ensure the integrity of control systems utilizing a 2625 volume booster in conjunction with a 377 trip valve, apply supply

pressure to the volume booster and to the volume tank (volume tank not required on 377L trip valve) through a check

valve. Failure to install the check valve properly will allow the cylinder pressure to bleed back through the open volume

booster supply port upon loss of supply pressure. The actuator may not fail as intended.