Instruction Manual

D200319X012

377 Trip Valve

August 2012

8

WARNING

Personal injury or property damage could result from bursting of parts due to temperature fluctuations or extreme heat. If

temperature fluctuations or extreme heat cannot be avoided, use a relief valve to protect the volume tank.

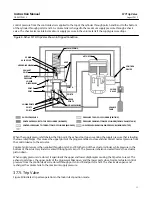

4. Read the following information before making pressure connections:

a. Trip valve port A must receive the operating pressure that is intended for the top of the actuator cylinder.

Depending on the actuator type and accessories being used, this operating pressure will be from a valve

positioner or switching solenoid.

b. Trip valve port B must provide operating pressure to the top of the actuator cylinder. Depending on the actuator

type and accessories being used, connect this port to the manifold assembly, to the top of the cylinder, or to the

cylinder connection on the hydraulic snubber (if one is used).

c. Trip valve port C must provide a fail‐mode outlet for the operating pressure to or from the top of the actuator

cylinder. For the fail‐down mode, connect this port to the volume tank. For the fail‐up mode, vent this port to

atmosphere. For the lock‐in‐last‐position mode, plug this port.

d. Trip valve port D must receive the operating pressure that is intended for the bottom of the actuator cylinder.

Depending on the actuator type and accessories being used, this operating pressure will be from a valve

positioner or switching solenoid.

e. Trip valve port E must provide operating pressure to the bottom of the actuator cylinder. Always connect this

port to the bottom of the actuator cylinder.

f. Trip valve port F must provide a fail‐mode outlet for the operating pressure to or from the bottom of the actuator

cylinder. For the fail‐down mode, vent this port to atmosphere. For the fail‐up mode, connect this port to the

volume tank. For the lock‐in‐last‐position mode, plug this port.

Operating Information

Calibration

This calibration procedure assumes that the trip valve is mounted on the actuator (or other device) and that all piping

and the appropriate volume tank (if necessary ) are installed. All key numbers refer to figure 10. For the appropriate

fail‐mode schematic, see figure 7, 8, or 9.

WARNING

The following procedure requires taking the trip valve out of service. To avoid personal injury and property damage by an

uncontrolled process medium, provide some temporary means of control of the process medium while the trip valve is out

of service.

1. Remove the adjusting screw cap (key 1).

2. Loosen the hex nut (key 3), and turn the set screw (key 2) counterclockwise until all loading is removed from the

spring (key 6).