Instruction Manual

D200319X012

377 Trip Valve

August 2012

6

the appropriate flow path C

v

value listed in table 1 for the trip valve. A regulator with insufficient capacity may allow

supply pressure to droop, which can cause the trip valve to trip again and begin a trip‐reset cycle. An example of an

appropriate supply regulator to use with a 377 trip valve is a 64 regulator; its capacity is usually great enough to meet

the demands of most trip valve/actuator combinations. Determine the requirements of your trip valve/actuator

combination for proper selection of a supply regulator.

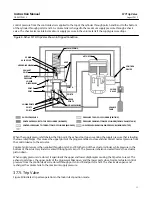

Figure 6. Fisher 2625 Volume Booster used with 377L Trip Valve

2625

1/2 O.D. TUBING

PISTON

ACTUATOR

POSITIONER

3/4 NPT

CHECK VALVE

3/4 NPT OR

1/2 NPT PIPING

SUPPLY

377L

i2P-100/67CFR

3/8 O.D.

TUBING

TYPICAL

NOTES:

1. 3/4 NPT CHECK VALVE AND 1/2 OR 3/4 NPT PIPING ARE REQUIRED.

2. THE SUPPLY PRESSURE REGULATOR SPECIFIED MUST HAVE ADEQUATE CAPACITY FOR 2625 BOOSTERS. ALSO, IF THE 2625 BOOSTER IS TO BE NIPPLE MOUNTED, THE BOOSTER MUST

BE MOUNTED TO A 1/2 NPT OR LARGER CYLINDER CONNECTION. SOME SMALLER CYLINDERS CANNOT BE TAPPED THIS LARGE; CONTACT YOUR EMERSON PROCESS MANAGEMENT

SALES OFFICE FOR AVAILABILITY ON SPECIFIC TYPES AND SIZES.

3/4 NPT OR

1/2 NPT PIPING

21B3153‐B

Note

During normal operation, an adequately sized supply regulator maintains a greater supply pressure than the pressure demand of

the trip valve and control devices. However, if the normal actuator piston position is not relatively close to the actuator piston fail

position during startup, or during the restoration of supply pressure, the regulator supply pressure may droop and cause the trip

valve to trip again and begin a trip‐reset cycle. To prevent this, perform the following steps:

1. Adjust the instrument (control device) pressure to position the actuator piston as it is positioned in the fail mode.

2. Restore the supply pressure to the normal operating range.

3. Manually reset the instrument pressure for normal operation.