9

require a three-wire cable (2 phases and

earth) with a minimum cross section area

equal to 2.5 mm².

4. OUTPUT CONNECTIONS

The welding cables are connected using

fast-connector plugs.

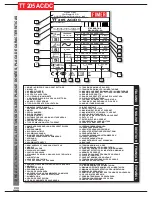

4.1 MMA Welding connections

1)

Connect the electrode clamp to the

special socket on the front panel of the unit

(Fig 1 – 35). Lining up the peg and the

groove, insert the plug and screw it in well

clockwise. Do not over-tighten.

Check the direct polarity Led (Fig. 1 - 30) is

ON.

2)

Connect the earth cable to the special

socket on the front panel of the unit (Fig 1 –

38) Lining up the peg and the groove, insert

the plug and screw it in well clockwise. Do

not over-tighten.

WARNING

: Some electrodes require

negative polarity on the electrode clamp

and positive polarity on the earth cable. In

that case, invert polarity using the Fig. 1 -

35 button. Always check the electrode

packaging for instructions regarding the

required polarities!

4.2 TIG WELDING CONNECTIONS

1)

Connect the earth cable to the special

socket on the front panel of the unit (Fig. 1

– 38). Lining up the peg and the groove,

insert the plug and screw it in well

clockwise. Do not over-tighten.

2)

Connect the torch to the appropriate

socket (Fig 1 – 35).

Lining up the peg and the groove, insert the

plug and screw it in well clockwise. Do not

over-tighten.

Connect the torch remote signal connector

to socket 36 (Fig.1) on the front panel of the

unit. Do not over-tighten.

5. GAS CYLINDER AND GAS

PRESSURE

REGULATOR

CONNECTIONS

Only for TIG Welding: Skip this charter

entirely if the welder is to be used for MMA.

Before connecting the gas cylinder, check

it contains pure Argon gas.

Always use welding torches with control

buttons.

While referring to Figure 3, follow these

instructions carefully:

1.

Connect the pressure regulator (2) to the

gas cylinder (3). Tighten the bolt (6)

between the regulator (2) and the cylinder

(3). Do not overtighten to avoid damaging

the cylinder valve (1).

2.

Connect the gas hose of the torch (4) to

the pressare regulator (2) and clamp

securely using a clasp (5). (Alternatively

use cylinder and hose fast connectors).

3.

Connect the other end of the gas hose

(6) to the socket on the rear panel of the

welder unit (Fig.2 – 42).

4.

Connect the gas hose from the torch to

the appropriate socket (7) on the front panel

of the unit (37 di fig 1).

4

3

2

1

6

2

5

1

3

Fig.3

Summary of Contents for TT165 AC/DC

Page 1: ...InstructionManual TT165 AC DC TT205 AC DC TT165 AC DC TT205 AC DC ...

Page 4: ......

Page 5: ...TT165 AC DC TT205 AC DC ...

Page 10: ...X ...

Page 12: ......

Page 30: ...20 NOTE ...

Page 32: ...Cod 910 100 333GB REV00 ...