The handling with fuels requires circumspective and ca-

reful handling. Imperatively observe the security advi-

ces.

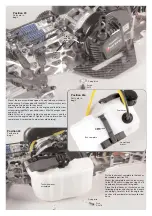

- Refuel only if the engine is switched off!

- Take off the body.

- Thoroughly clean the area around the fuels nipple.

- Remove the fuel filler cap and carefully fill in the fuel mixture.

- Smoking or any kind of open fire is not admitted.

- Fuels might contain solvent-like substances. Avoid contact with skin and ey-

es. Wear gloves for refueling. Do not inhale fuel vapors.

- Do not spill any fuel. If you have spilled fuel immediately clean the engine

and the model.

- Make sure that no fuel will get into the soils (environmental protection). Use

an appropriate mat.

- Do not refuel in enclosed rooms. Fuel vapors accumulate at the soil (risk of

explosion).

- Transport and store fuels only in admitted and labeled canisters. Keep fuel

out of the range of children.

- The operator is responsible for any damages caused to third persons in the

operating range of the model, respectively of the engine, if they are injured

or in case of property damage.

- The model must only be passed on to persons who are familiar with this mo-

del and its operation, always provide the operating manual.

- Persons with implanted heart pacemakers must not work on running engi-

nes and on live parts of the ignition system when the engine is being star-

ted.

- The engine must neither be started nor operated in enclosed rooms (wi-

thout sufficient ventilation).

- When starting the engine, avoid inhaling the exhausts.

- The model must neither be started nor operated without air filter or without

exhaust system.

- Before every start perform a functional check of the safety-relevant parts.

- The throttle rods must always return automatically to the idle position.

- Any cleaning, maintenance and repair works must only be performed with

the engine being switched off. The engine and silencers are getting very

hot. In particular do not touch the silencer.

Comments regarding the construction manual:

Before starting the assembly please see through this construction manual.

This way you will get an overview of the whole execution.

Please check by means of the parts or bag list if the construction kit is com-

plete and also check the weight of the individual bags for the positions. Only

this way you may be sure that all parts which you need for the assembly are

available. If a part is missing, please immediately contact your specialized

dealer.

Table of contents

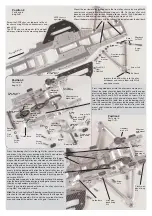

Position 1: Differential gear

Position 2-7: Rear axle, gearwheel drive

Position 8: Shock absorber

Position 9-10a: Assembly shock absorber, stabilizer - rear axle

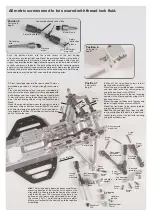

Position 11-19a: Front axle

Position 14-17: Servos, receiver

Position 18-19a: Assembly shock absorber, stabilizer - front axle

Position 12-13: Servo saver, track rods, steering rods

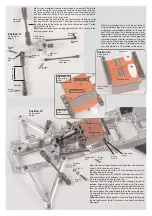

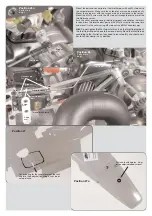

Position 19-23: Engine, manifold, airbox, clutch

Position 23-24a: Engine assembly, tank

Position 25-25a: Tuning pipe

Position 18: Throttle rods

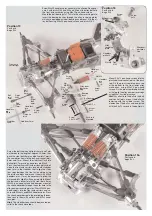

Position 28-29: Front spoiler, rear spoiler

Position 30-31b: FG Magura hydr. brake system front and rear

Position 32-33b: Tuning disk brake front and rear