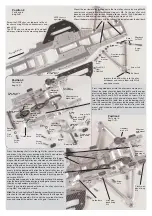

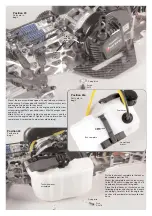

Push the distance disks into the round recess of the ball driving

axle as well as into the ball diff. axle. Mount the protection bellows to the ball dri-

veshafts according to the illustration. Lubricate the ball range a little when put-

ting on the protection bellow. Apply lubrication grease on the ball holes of the dri-

veshafts and press in the balls. The balls will be held by the lubrication grease

and this way the driveshaft can be mounted more easily. Now press the complete

ball driveshaft into the ball differential axle and the ball driving axle. Shift the pro-

tection bellows over the ball diff. axles and the ball driving axles.

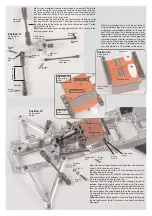

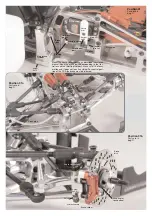

Position 7

Parts are in

bag B

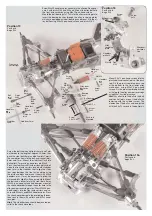

Driving

shaft

mounted

Left alloy

upright

Headless

pin 6x6

Wheel nut

M6

Square wheel

14 mm

Screw

4x12

Distance

bush

Ball bearing

8x22x7

Ball bearing

8x22x7

Pay attention

to the slant

Screw

5x16

Screw

5x16

Screw

5x20

Rear axle

plate left

Screw

5x20

Bevel

washer

Driving dir

ection

Track rod

mounted

Screw

2,9x13

Screw

2,9x13

Rear upper

wishbone

left mounted

Screw

4x35

Screw

4x35

Ball diff. axle

Alloy rear axle

mount left

approx.

21,5mm

appr

ox.

39mm

approx.

10,5mm

Hint:

The left and right upper wishbones are different,

mounting direction of the steel ball with collar on the

alloy upright is showing to the bottom and the shorter

side faces the rear. The clearance of the balls in the

ball-and-socket joints can be adjusted with the help of

the screws 2.9x13. The left and right rear axle plates

differ, pay attention that the slant shows to the top when

assembling.

Apply

lubrication

grease.

Lubricate ball driveshaft a little.

Protection bellow

Ball diff. axle

Ball driving

axle

Distance

disks

Balls for dri-

ving shaft

Position 5

Parts are in

bag B

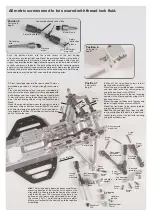

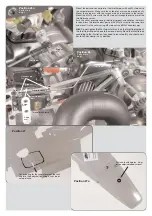

1.

Press the cylinder pins into the square wheel 14mm as

described in position 6, use high-strength screw reten-

tion.

Press the ball driving axles of the pre-assembled dri-

veshafts into the alloy uprights which are equipped with

ball bearings and then mount the square wheel driver

14mm with recess facing the ball bearing on the flat si-

de of the ball driving axle by using the headless pins

M6x6.

Mount the alloy upright between alloy upright and alloy

wishbones using a countersunk screw M5x20 and bevel

disk (thin side facing the ball bush). The left and right al-

loy uprights are different. The milled surface for the bra-

ke has to face the rear.

2.

Mount 2,9x13 pan-head screws into all

plastic ball-and-socket joints.

Mount the pre-assembled upper wishbones

and track rods to the alloy rear axle mounts

using the pan-head screws M4x35.

Fix the rear axle plates with the slant showing

upwards to the alloy uprights by using M5x16

pan-head screws.

Mount the upper wishbones to the rear axle

plates using countersunk screws M5x20.

Mount the track rods to the rear axle plates

using cylinder screws M4x12.

Hint

: The left and right track rods are diffe-

rent, pay attention to the balls in the ball-and-

socket joints, mount the ball with lowering

using the cylinder screw.

All metric screws need to be secured with thread lock fluid.

Position 6

Parts are in

bag B