A

Technical appendix

42

Festo – GDCP-EXPT-KM-KOMP-EN – 1204a – English

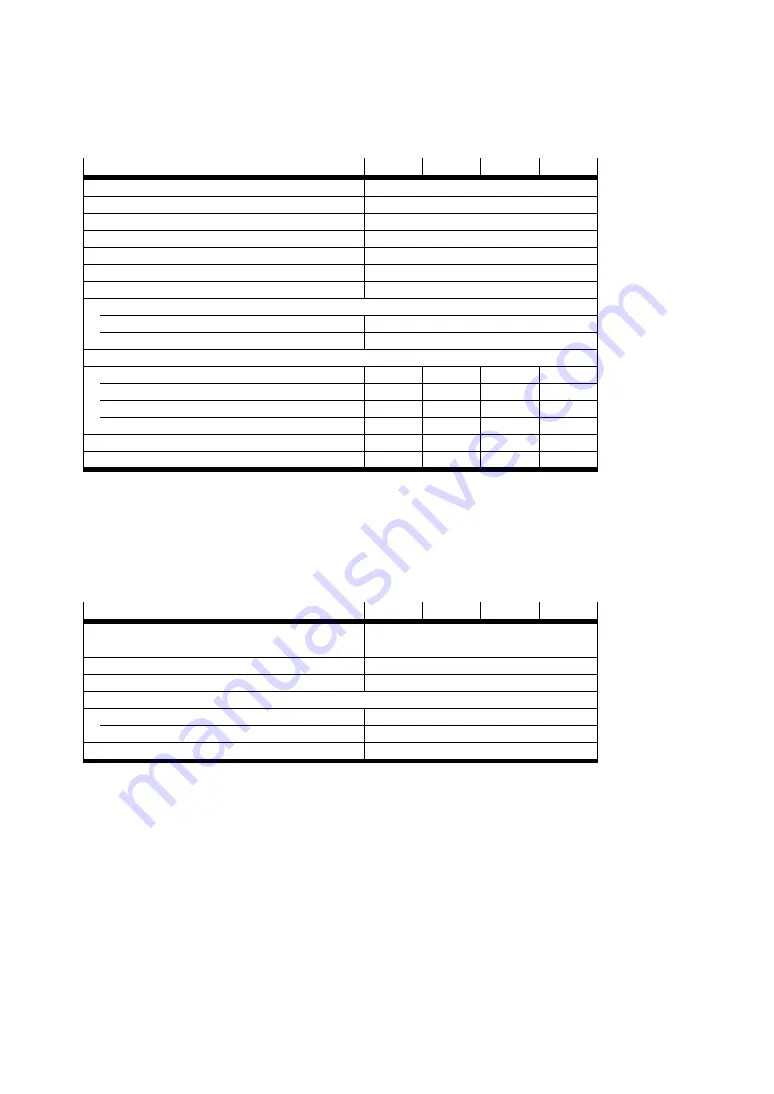

A.1.3

Dynamic

Size

45

70

95

120

Motor type

Servo motor

Max. acceleration

1)

[m/s

2

]

110

Max. speed

1)

[m/s]

7

Max. picking rate

1)5)

[picks/min]

150 (in 12 inch cycle)

Repetition accuracy

[mm]

± 0.1

Positioning accuracy

2)

[mm]

± 0.5

Track precision

3)

[mm]

± 0.5

Effective load

4)

With min. dynamic response

[kg]

5

With max. dynamic response

[kg]

1

Max. process force in Z direction

With working space

∅

[mm]

0

0

0

0

Process force in Z direction

[N]

1300

1000

1000

850

With working space

∅

[mm]

112.5

175

237.5

300

Process force in Z direction

[N]

1000

750

750

750

Max. frame strength horizontal

[N]

± 145

± 150

± 200

± 215

Max. frame strength vertical

[N]

± 250

± 290

± 325

± 475

1)

When used in conjunction with motor controller CMMP-AS-C5-3A and controller CMXR (multi-axis control).

2)

Only with calibrated system (order code S)

3)

Only with calibrated system (order code S) and a speed of

≤

0.3 m/s

4)

Sum of load mass and accessories attached to the front unit

5)

With a max. transient response of ± 0.5 mm

Tab. A.3

A.1.4

Operating and environmental conditions

Size

45

70

95

120

Operating medium

Compressed air in accordance with

ISO 8573-1:2010 [5:4:1]

Ambient temperature

[°C]

0 … +40

Storage temperature

[°C]

–10 … +60

Air humidity

–

[%]

5 … 95, non-condensing

T1 to T4

[%]

20 … 80, non-condensing

Duty cycle

[%]

100

Tab. A.4