7

Operation

Warning

Make sure that in the travel range of the drive

– Nobody can reach into the path of the movable

components (e.g. by providing a protective

guard).

– There are no foreign objects (e.g. hexagon

wrench when setting the end position under

pressure).

It must not be possible to touch the drive until

the moveable mass has come to a complete rest.

Fig. 26

8

Maintenance and care

Cleaning:

Exhaust the DGSL.

Clean the DGSL if required with a soft, damp cloth. Use non-abrasive cleaning

agents.

Lubricate the following components of the DGSL:

Component

Ungreased surfaces of

the piston rod

Roller bearing of the

slide

Lubrication interval

As required (e.g. after cleaning), otherwise the DGSL is

maintenance-free

Reason for lubrication

Humidity protection and

gliding quality

Gliding quality

Lubricating point

Piston rod

Guide rail

Lubricating procedure

Push the slide backwards and forwards by hand when

lubricating (even distribution of grease)

Lubricating grease

LUB-KC1 from Festo (

è

Spare parts catalogue at www.festo.com)

Fig. 27

Check to see if more frequent lubrication is required. This may be the case with:

– High temperatures

– strong accumulation of dirt

– fat solvent fluids or vapours in the vicinity.

Check the cushioning components

1

every 2 million cycles for signs of wear

(e.g. abrasion, oil leakage, ...).

Replace the cushioning elements if there are signs of wear, at the latest after

every 5 million cycles (keep clamping component in a safe place when dismant

ling the DGSL).

9

Repair and disassembly

Exhaust the complete system and the device.

Recommendation: Send the product to our repair service.

This way, the fine tuning and tests that are required will be taken into particular

consideration.

Note

In particular, attempting to repair the slide guide yourself is strongly discour

aged.

Information about spare parts and aids can be found at:

www.festo.com/spareparts.

To replace the integrated cushioning components

1

:

Observe the section “Precision adjustment of the

end positions” in the chapter “Commissioning”.

Fig. 28

aE

Proceed as follows:

1. Loosen the clamping component

aE

on the cushioning component (clamping

component can fall out).

2. Replace cushioning component (

è

Accessories at www.festo.com/catalogue).

– DYEF-S-…-Y1 at

DGSL-…-E

– DYEF-…-Y1 at

DGSL-…-P

– DYEF-…-Y1F

at DGSL-…-P1

– DYSW-…-Y1F

at DGSL-…-Y3

– DYSW-…-Y1F

at DGSL-…-Y11

3. Carry out the precision adjustment of the end positions (

è

6 Commissioning).

10

Accessories

Note

Please select the corresponding accessories from our catalogue

(

è

www.festo.com/catalogue).

11

Troubleshooting

Malfunction

Possible cause

Remedy

Uneven movement of the

moving mass

One-way flow control valve not

installed correctly

Check the flow control

functions (supply or exhaust

air flow control)

Bearing surfaces dirty

Clean the bearing surfaces

Hard impact at the end posi

tion

Speed too high

Reduce speed

no or too low cushioning

– Adjust shock absorber/

fixed stop again (

è

6.1 Pre

paration of commissioning)

– Reduce speed

– Check and, if necessary, re

place cushioning compon

ents

Missing air cushion

Simultaneous pressurization

of both compressed air supply

ports with subsequent ex

hausting of one side

Shock absorber defective

(only for DGSL-…-Y3)

Replace shock absorbers

(

è

Effective load too large

Reduce effective load

Slide in initial position despite

pressurization

Tubing connection error

– Check blanking plug

– Checking the tubing con

nection

The slide speed is too low

– Pressurization cross-sec

tional area too small

– Flow control valves set in

correctly

Check pressurization cross-

sectional area and adjustment

of throttle

Fig. 29

12

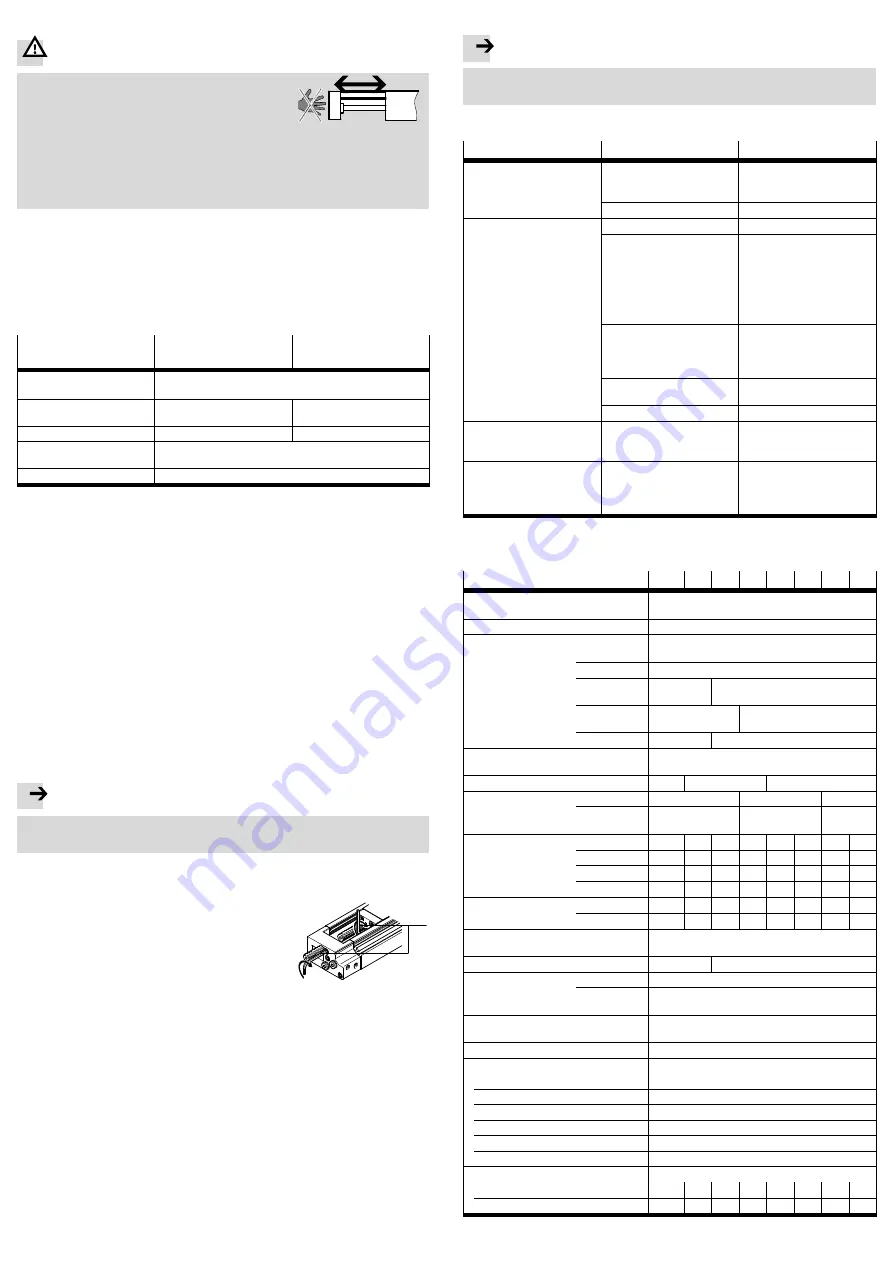

Technical data

DGSL

4

6

8

10

12

16

20

25

Design

Double-acting drive with yoke kinematics and ball-

bearing cage guide

Mounting position

Any

Cushioning

E/P

Flexible cushioning, without metal end stop, both

ends

P1

Flexible cushioning, with metal end stop, both ends

Y3

–

With progressive shock absorber,

both ends

Y11

–

With progressive shock ab

sorber, both ends

N

–

Without cushioning

Operating medium

Compressed air in accordance with

ISO8573-1:2010 [7:4:4]

Operating pressure

[bar]

2.5 … 8 1.5 … 8

1 … 8

Pneumatic connection

M3

M5

G

x

N

–

M5 suitable for

10-32 UNF

x

NPT

Impact energy in the end

positions

E/P

[Nm]

0.015

0.05

0.08

0.12

0.25

0.35

0.45

0.55

P1

[Nm]

0.005

0.02

0.03

0.04

0.06

0.12

0.2

0.25

Y3

[Nm]

–

–

0.5

1

2

4

7

10

Y11

[Nm]

–

–

–

0.5

1

2

4

7

Theoretical force

at 6 bar

Advance [N]

17

30

47

68

121

188

295

483

Return

[N]

13

23

40

51

104

158

247

415

Max. permissible forces

and torques

è

Catalogue specifications:

www.festo.com/catalogue/dgsl

Max. speed

[m/s] 0.5

0.8

Repetition accuracy

E/P

[mm]

0.3

P1/Y3/

Y11

[mm]

±0.01

Ambient temperature

[°C]

0… 60 (observe temperature range of proximity

sensors)

Note on materials

Free of copper and PTFE

Information on material

Housing, cover, yoke plate

Anodised wrought aluminium alloy

Screws

Steel

Piston rod, slide, adjusting screw

High-alloy stainless steel

Cover, stops, driver

Beryllium bronze, nickel-plated

Buffer

Nitrile rubber

Seals

Hydrated nitrile rubber, polyurethane

Weight

[kg]

Min. stroke

0.08

0.16

0.24

0.4

0.6

0.9

1.5

2.5

Max. stroke

0.1

0.23

0.45

0.8

1.5

2.0

4.3

6.1

Fig. 30