7

Assembly

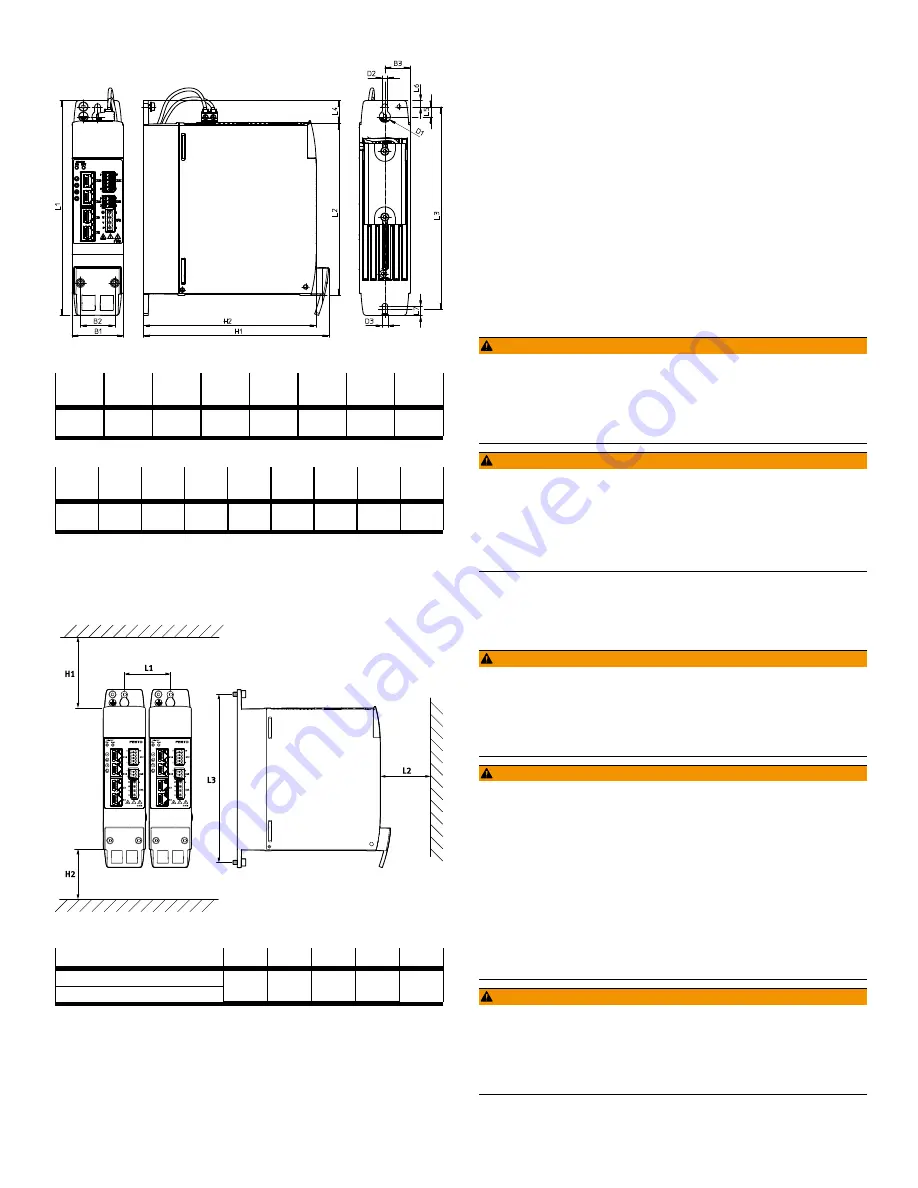

Dimensions

Fig. 5 Dimensions

Dimen-

sion

L1

L2

L3

L4

L5

L6

L7

[mm]

Approx.

212

170

200

22

10

6

9

Tab. 9 Dimensions part 1

Dimen-

sion

H1

H2

B1

B2

B3

D1

D2

D3

[mm]

Approx.

183

170

Approx.

50

34

Approx.

25

R5.5

5.5

5.5

Tab. 10 Dimensions part 2

7.1

Mounting distances CMMT-AS-...-3A (1-phase)

The servo drives of the CMMTAS series can be arrayed next to each other. When

arraying devices, the required minimum distance must be maintained so that the

heat generated during operation can be removed by allowing sufficient air flow.

Fig. 6 Mounting distances and installation clearance for CMMTAS...3A (1phase)

Servo drive

H1

H2

1)

L1

L2

L3

CMMTASC23A...

[mm]

CMMTASC43A...

[mm]

70

70

52

70

200

1) To ensure that clearance H2 is observed and that the motor and encoder cables are routed in the optimum

manner on the bottom of the housing, an installation clearance of 150 mm is recommended!

Tab. 11 Mounting distances and installation clearance

This means that a minimum lateral distance of 2 mm (52 mm – 50 mm) must be

observed in relation to neighbouring CMMTAS devices.

For adjacent thirdparty devices, Festo recommends a distance of at least 10 mm

(surface temperature of thirdparty device max. 40 °C). The double mating plug

for crosswiring of the connection [X9A] protrudes by approx. 6 … 7 mm over the

right side of the device. However, this does not create an obstacle for arraying

additional CMMTAS.

7.2

Installation

Assembly instructions

–

Use a control cabinet with degree of protection IP54 or higher.

–

Always install device vertically in the control cabinet (mains supply lines [X9A]

point upwards).

–

Screw device flat to a sufficiently stable mounting surface so that good heat

transfer from the cooling element to the mounting surface is ensured

(e.g. screw to the rear wall of the control cabinet).

–

Maintain minimum distances and installation clearance to ensure sufficient

air flow. The surrounding air in the control cabinet must be able to flow

through the device from bottom to top without hindrance.

–

Take into account the required clearance for the wiring (connecting cables of

the device must be routed from above and from the front).

–

Do not mount any temperaturesensitive components near the device. The

device can become very hot during operation (switchoff temperature of the

temperature monitoring

è

Technical data).

–

When assembling several devices in a device compound, consider general

rules for crosswiring. For intermediate circuit coupling, higherpower devices

must be placed closer to the mains supply.

To enable attachment to the rear panel of the control cabinet, the servo drive

cooling element has a slot on the top in the shape of a keyhole and an ordinary

slot on the bottom.

Assembly of the servo drive

WARNING!

Danger of burns through hot escaping gases and hot surfaces.

In case of error, incorrect wiring or incorrect polarity of the connections [X9A],

[X9B] and [X6A], internal components can be overloaded. High temperatures can

develop and hot gases can be released.

•

Have an authorised electrician perform the installation according to the docu

mentation.

WARNING!

Danger of burns from hot housing surfaces.

Metallic housing parts can accept high temperatures in operation. In particular,

the braking resistor installed in the profile on the back side can become very hot.

Contact with metal housing parts can cause burn injuries.

•

Do not touch metallic housing parts.

•

After the power supply is switched off, let the device cool off to room temper

ature.

•

Fasten the servo drive to the rear wall of the control cabinet with suitable

screws while complying with the assembly instructions.

8

Installation

8.1

Safety

WARNING!

Risk of injury from electric shock.

Contact with live parts at the power connections [X6A], [X9A] and [X9B] can result

in severe injuries or death.

•

Do not pull out power supply plugs while live.

•

Before touching, wait at least 5 minutes after switching off the load voltage to

allow the intermediate circuit to discharge.

WARNING!

Risk of injury from electric shock.

The leakage current of the device to earth (PE) is

>

3.5 mA AC or 10 mA DC.

Touching the device housing if there is a fault can result in serious injuries or

death.

Before commissioning, also for brief measuring and test purposes:

•

Connect PE connection on the mains side at the following positions:

–

Protective conductor connection (earthing screw) of the housing

–

PE pin of the connection [X9A] (power supply)

The cross section of the PE conductor must be at least equal to the cross

section of the line conductor L at [X9A].

•

Connect motor cable to connection [X6A] and the shield of the motor cable on

the front side to PE via the shield clamp of the servo drive.

•

Connect all additional PE conductors for the connections used.

•

Observe the regulations of EN 602041 for the protective earthing.

WARNING!

Danger of burns through hot escaping gases and hot surfaces.

In case of error, incorrect wiring or incorrect polarity of the connections [X9A],

[X9B] and [X6A], internal components can be overloaded. High temperatures can

develop and hot gases can be released.

•

Have an authorised electrician perform the installation according to the docu

mentation.