During installation and operation of this product, comply with all safety require

ments, statutes, codes, rules and standards relevant for the product, such as the

National Electrical Code (USA), Canadian Electrical Code (Canada) and regulations

of the US federal agency OSHA. When selecting the circuit breaker, comply with

the maximum permissible electrical protection for UL.

3

Additional information

–

Accessories

è

www.festo.com/catalogue.

–

Spare parts

è

www.festo.com/spareparts.

–

All available documents for the product and current versions of the firmware

and commissioning software

è

www.festo.com/sp.

4

Service

Contact your regional Festo contact person if you have technical questions

è

www.festo.com.

5

Product overview

5.1

Scope of delivery

Component

Number

Servo drive CMMTAS...

1

Instruction manual CMMTAS...

1

Tab. 6 Scope of delivery

5.2

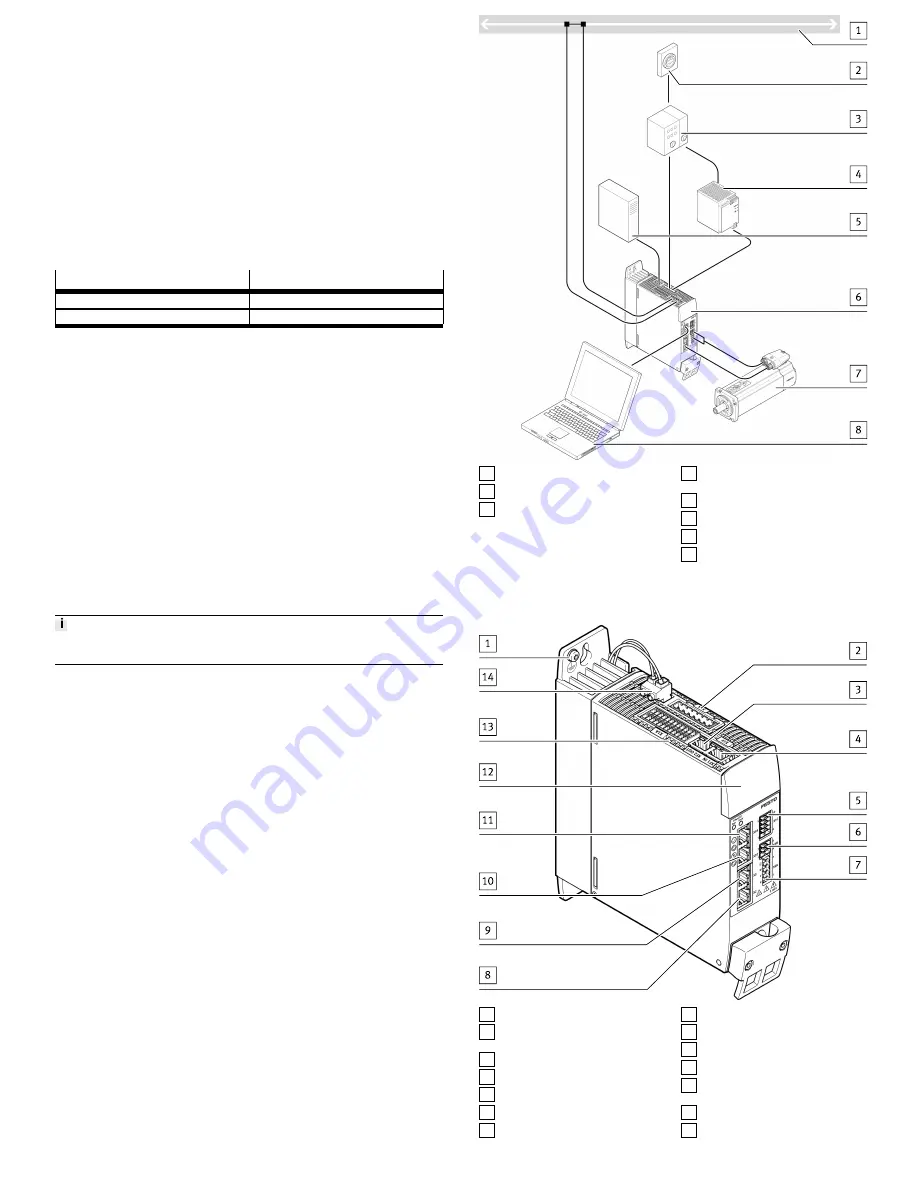

System structure

The servo drive CMMTAS is a 1axis servo drive. Depending on the product vari

ant, the following components, which are necessary for standard applications, are

integrated into the device or into the cooling profile of the device:

–

Mains filter (guarantees immunity to interference and limits conducted emit

ted interference)

–

Electronics for intermediate circuit voltage conditioning

–

Output stage (for motor control)

–

Braking resistor (integrated into the cooling element)

–

Brake chopper (switches the braking resistor in the intermediate circuit, if and

when required)

–

Temperature sensors (for monitoring the temperature of the power module

and of the air in the device)

–

Fan in cooling profile (depending on product variant)

The servo drive features a Realtime Ethernet interface for process control. Vari

ous bus protocols are supported depending on the product design (EtherCAT, Eth

erNet/IP or PROFINET).

The device can be parameterised via a PC using either the Realtime Ethernet

interface or the separate standard Ethernet interface.

Festo recommends use of servo motors, electromechanical drives, lines and

accessories from the Festo accessory programme.

1 Bus/network

2 Main switch

3 Circuit breaker/fuses and allcur

rentsensitive RCD (residualcur

rentoperated protective device)

(optional)

4 Power supply unit for logic voltage

supply 24 V DC (PELV)

5 External braking resistor (optional)

6 Servo drive CMMTAS

7 Servo motor (here EMMEAS)

8 PC with Ethernet connection for

parameterisation

Fig. 3 System structure (example)

5.2.1

Overview of connection technology

1 PE connection, housing

2 [X9A] Mains voltage, intermediate

circuit voltage and logic voltage

3 [XF2 OUT] RTE interface port 2

4 [XF1 IN] RTE interface port 1

5 [X1C] Inputs/outputs for the axis

6 [X6B] Motor auxiliary connection

7 [X6A] Motor phase connection

8 [X2] Encoder connection 1

9 [X3] Encoder connection 2

10 [X10] Device synchronisation

11 [X18] Standard Ethernet

12 [X5] Connection for operating unit

(behind the blind plate)

13 [X1A] I/O interface

14 [X9B] Connection for braking res

istor

Fig. 4 Connections of the CMMTAS...3A