FENIX IMVICO

TK-41 OPERATION MANUAL

7/88

•

HEAD CLEANING PROCEDURE AND PRECAUTIONS

.

Do not clean the thermal head immediately after printing because thermal

head and its periphery are hot during and after printing.

Do not use sandpaper, cutter knives etc. when cleaning. They will damage the

heat elements.

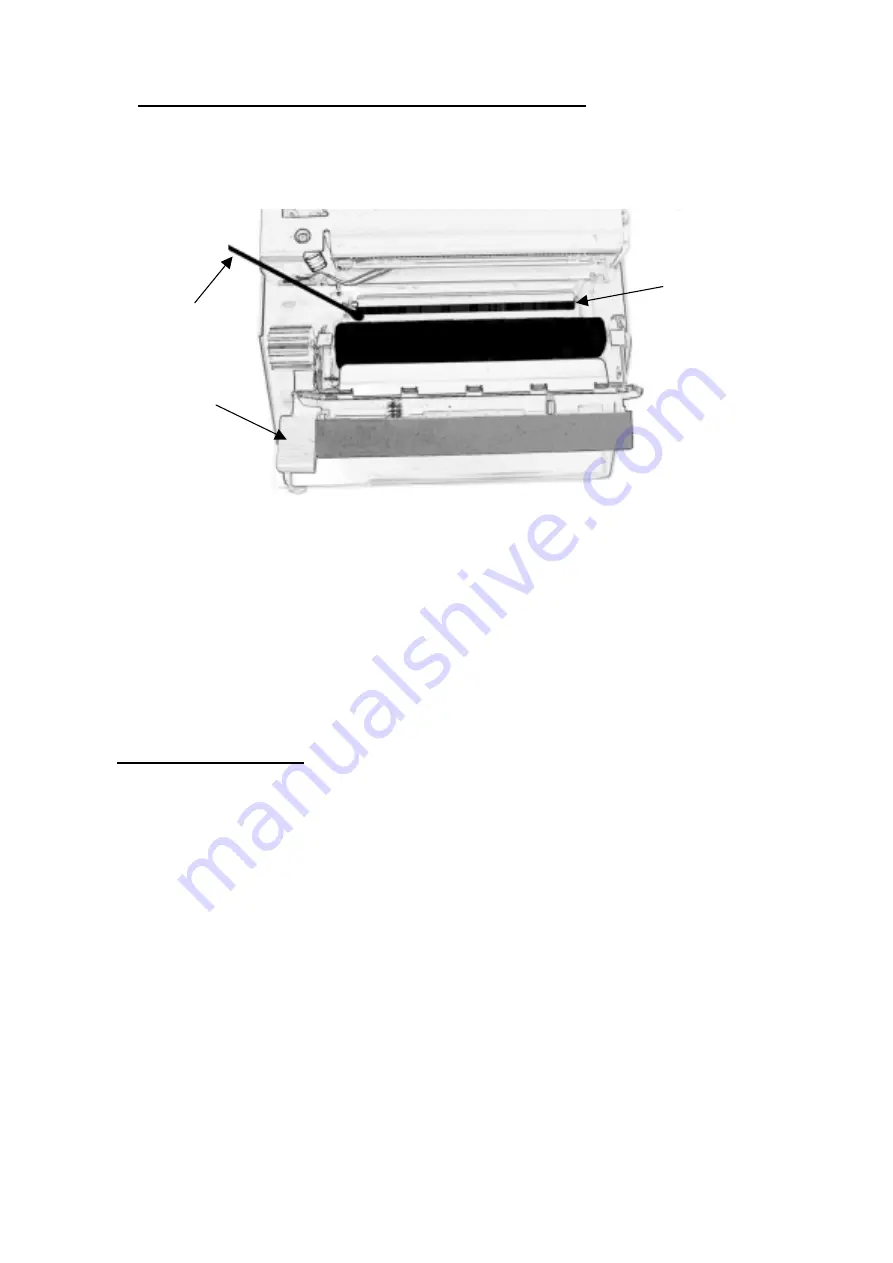

Fig a. Head cleaning procedure

Turn off the printer. Turn the release lever in the direction of the arrow. Clean

the heat elements using alcohol (ethanol, methanol, or IPA) and a cotton swab.

Wait until the alcohol dries and close the platen block. Fenix recommends

cleaning the thermal head periodically (generally every 3 months) to maintain

receipt print quality.

RECOMMENDATIONS

•

Before connecting any input interface, verify the correct operation of the

TK-41 printer with self test feature.

•

Place the TK41 in such a way that connection wires are not crushed or

twisted

.

Thermal head

Cotton swab

Head-up

lever