Assembly - 1370, 1385, 1395, 13114 Backsaver Auger

70

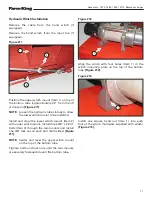

Figure 207

Install the mounting bracket (Item 1) onto the valve

block using three 1/4” x 2-3/4” bolts, three 1/4” flat

washers and three 1/4” lock nuts (Item 2). Tighten

bolts and lock nuts

[Figure 207]

.

Figure 208

Install the valve block assembly onto the left side

of the input box.

Install two 3/8” x 1” bolts (Item 1) through the

valve block mounting bracket and input box

mount. Install two 3/8” lock nuts on the bolts and

tighten

[Figure 208]

.

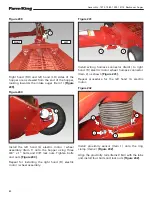

Figure 209

Apply teflon tape to the threads (Item 1) of the

hydraulic hose fitting, then install and tighten the

male quick coupler fitting (Item 2)

[Figure 209]

.

Repeat for second quick coupler hose.

Figure 210

Install the quick coupler hoses (Item 1) onto the

control valve

[Figure 210]

.

1

1

1

1

2

1

2

Summary of Contents for 1370

Page 1: ...062019 FK429 ASSEMBLY MANUAL BACKSAVER AUGER Models 1370 1385 1395 13114...

Page 2: ......

Page 92: ...Assembly 1370 1385 1395 13114 Backsaver Auger 90...

Page 93: ......