DC Servo Drive System Manual Ver: 0009

DC - 21/32

Installation

5.1

GENERAL CONSIDERATIONS

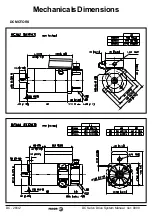

About the Motor:

Remove the anti-corrosion paint of the shafts before mounting them on to the machine.

The motor may be mounted as described in the first chapter

Watch for the ambient conditions:

Mount it somewhere that is dry, clean and accessible for maintenance.

-remember that it meets the IP44 degree of protection.

It must be easily cooled. Avoid corrosive or flammable environments.

Guard the motor with a cover if it is exposed to splashes.

Use flexible couplings for direct transmission.

Avoid radial and axial loads on the motor shaft.

Avoid hitting the shaft.

Use some tool that is supported in the

threaded hole on the shaft to insert the

pulley or the gear.

About the Drive:

The module must be installed in an electrical enclosure that is clean, dry free of dust, oil or other

pollutants - remember that its degree of protection is IP20-. Never install it exposing it to flammable

gases. Avoid excessive heat and humidity. The ambient temperature must never exceed 45°C

(113°F).

Mount the modules vertically (as shown on the photos). Avoid vibrations.

Leave at least 30 cm of clearance above and below the module for better air flow.

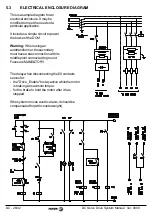

About the connections:

All the cables must be shielded, to reduce the interference on the control of the motor due to the

commutation of the PWM. The shield of the motor power cable must be connected to the chassis

screw at the bottom of the module and it, in turn, taken to Mains ground.

A transformer MUST BE used. It must serve as a filter to limit the start-up current to the maximum

allowed by the unit. See characteristics on page 10.

The command signal lines must be shielded twisted pairs. The shield must be connected to the

voltage reference at the module (pins 2, 4 or 10).

Keep the signal cables away from the power cables.

All the pins with the GND symbol (2, 4, 10) are the same electrical point and are interchangeable.