DC Servo Drive System Manual Ver: 0009

DC - 19/32

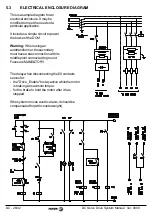

Adjustment potentiometers:

Acc/Dec Ramps: To adjust the ramp filtering the velocity command. Ramps with a duration of up

to 10 seconds may be applied for a 10 volt step of analog voltage.

Turning this pot clockwise means smoother behavior (longer ramp).

WATCH OUT! If jumper J2 of the identity module is set in the (bc) position, no ramps will be

applied.

Max. Current Limit: Each drive is factory set to provide the maximum current to the motor which

corresponds to the maximum value of the current command. This adjustment may be used to

decrease the value of that current limit.

Turning this pot clockwise allows more current to flow through the motor.

PI Gain: For adjusting the overall gain of the velocity PI.

Turning this pot clockwise increases the gain and, therefore, makes the system perkier.

Max. Speed: Every drive is factory set so the motor turns at its maximum speed when applied

maximum velocity command.

In this case, this pot will be turned 3/4 of its full travel. Therefore, it may be used to limit or force

slightly the maximum motor speed.

Turning this pot clockwise allows greater speed.

Offset: To compensate for the difference between the velocity command and the actual motor

speed.

These are the names of the identity

modules (IM) for each Motor-Drive set.

And these are the values of the passive

components on each of those cards.

IM Board

RIT

RAJFV

RTV1

DCS-08

DCS-14

DCS-08

DCS-14

DCM21.40A

IM-2140A-08

DCM21.40A

75K

5,6K

82K

DCM22.40A

IM-2240A-08

IM-2240A-14

DCM22.40A

39K

68K

5,6K

82K

DCM23.25A

IM-2325A-08

IM-2325A-14

DCM23.25A

43K

82K

10K

39K

DCM41.12A

IM-4112A-08

DCM41.12A

130K

22K

10K

DCM41.20A

IM-4120A-08

IM-4120A-14

DCM41.20A

75K

130K

12K

27K

DCM41.30A

IM-4130A-08

IM-4130A-14

DCM41.30A

47K

91K

8,2K

56K

DCM42.12A

IM-4212A-08

IM-4212A-14

DCM42.12A

68K

130K

22K

10K

DCM42.20A

IM-4220A-08

IM-4220A-14

DCM42.20A

39K

75K

12K

27K

DCM42.30A

IM-4230A-14

DCM42.30A

56K

8,2K

56K

DCM43.12A

IM-4312A-08

IM-4312A-14

DCM43.12A

43K

82K

22K

10K

DCM43.20A

IM-4320A-14

DCM43.20A

47K

12K

27K

DCM43.30A

IM-4330A-14

DCM43.30A

39K

8,2K

56K

DCM51.12A

IM-5112A-14

DCM51.12A

62K

22K

10K

DCM51.20A

IM-5120A-14

DCM51.20A

39K

12K

27K

DCM52.12A

IM-5212A-14

DCM52.12A

47K

22K

10K

General purpose:

IM-0000

RAPT = 15K

RAP1 = 82K

CAI1 = 100nF