22

ENGLISH

ENGLISH

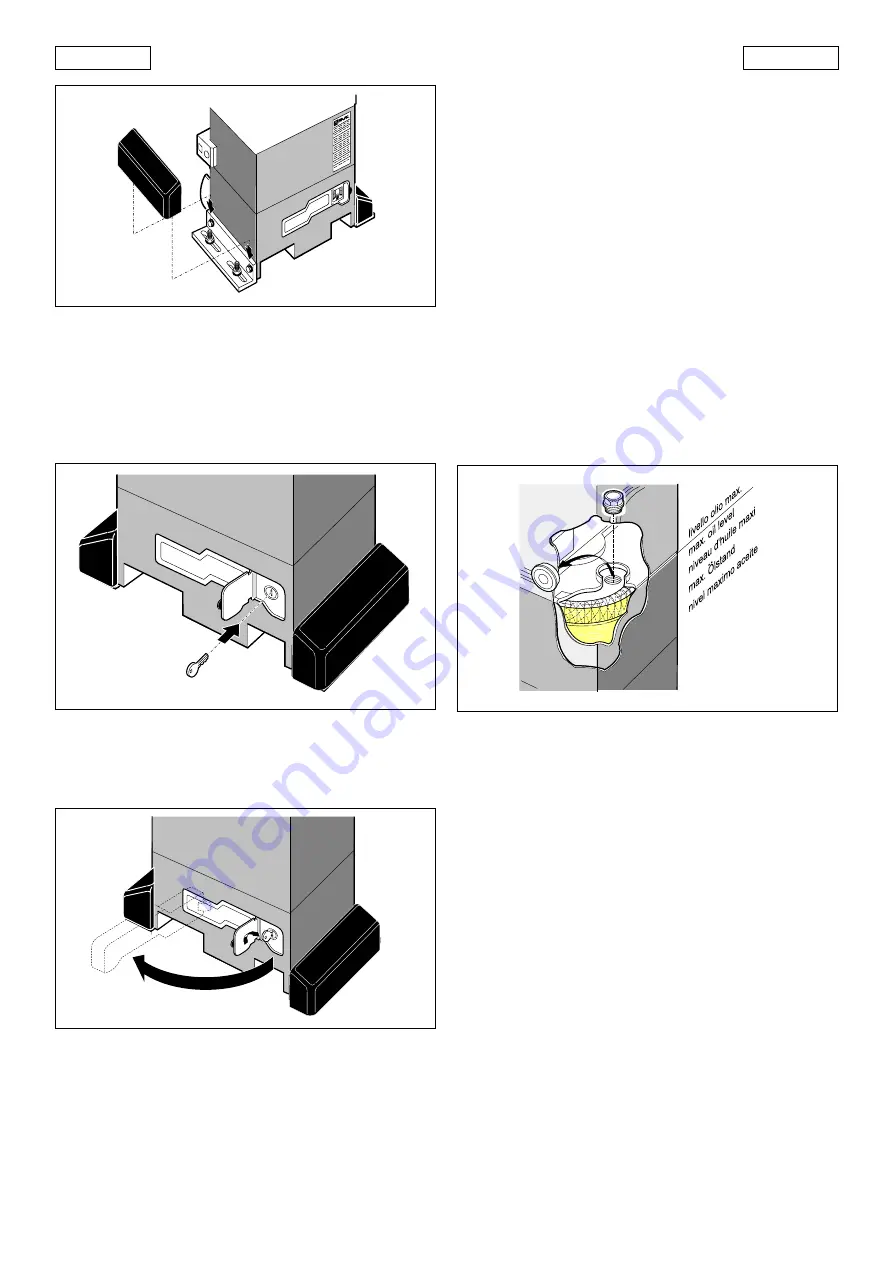

Fig. 36

Fig. 37

Fig. 38

Fig. 35

Give the customer the User Guide. Explain correct use and

operation of the gear motor and draw attention to the potential

danger zones of the automation.

7. MANUAL OPERATION

If it is necessary to operate the gate manually due to a power

failure or malfunction of the automation, release the electric

lock using the special key and move the gate leaf manually.

If this is not sufficient (serious mechanical malfunction), carry

out the following operations on the release system:

1)

Open the lock cover and insert the key supplied in the lock

(Fig.36).

2)

Turn the key anti-clockwise.

3)

Remove the key and close the lock cover.

4)

Move the gate until the release device engages.

9. SPECIAL APPLICATIONS

There are no special applications.

10. MAINTENANCE

When performing maintenance, always check that the anti-

crushing clutch is correctly adjusted and that the safety devices

operate correctly.

10.1. TOPPING UP WITH OIL

Check the quantity of oil in the operator periodically.

For medium-low duty cycles an annual check is sufficient; for

more intensive use, check every 6 months.

To access the oil reservoir, remove the oil filler cap (Fig.1 ref.10).

The oil level should be up to the copper windings of the electric

motor (Fig. 38).

To top up, pour in oil to the correct level.

Use exclusively FAAC XD 220 oil.

11. REPAIRS

For repairs contact an authorised FAAC Repair Centre.

2)

Turn the key clockwise and pull out the release lever as

shown in Fig.37.

3)

Open or close the gate manually.

8. RETURN TO NORMAL OPERATION

To prevent accidental operation of the gate during this

procedure, turn off the electricity supply to the system before

relocking the operator.

1)

Close the release lever.