16

| Tritex

®

TTX Series DC Actuator Installation & Maintenance Instructions

Curtiss-Wright | Rev D | PN75667 | 8/1/22

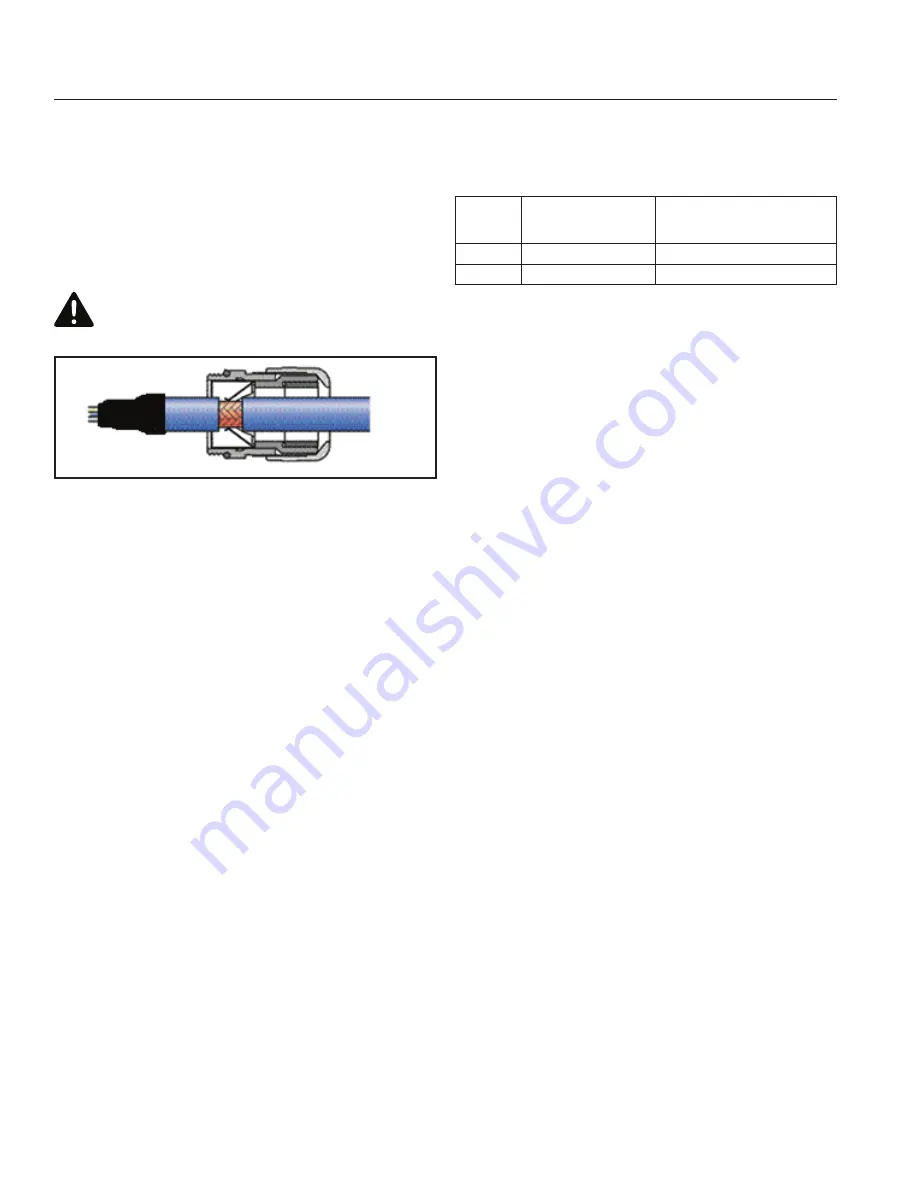

The connectors and cables supplied by Curtiss-Wright properly

terminate shields. If cable glands are used, make sure the

cable gland has a feature to make contact between the metal

body and shield and that the outer jacket is removed as

recommended by gland manufacturer and installed according to

manufacturer instructions. Example shown in diagram below. A

shield connection such as the one shown does not qualify as a

PE connection.

CAUTION!

Avoid Loose Conductive Material

Always apply tape or heat shrink to the end of the shield to

than rated voltage results in proportionally reduced maximum

speed. Refer to Torque/Speed diagrams in catalog for additional

information.

Actuator

Size

Input Voltage (Volts DC)

Rated Continuous Input Current

(Amps)

60 mm

12 to 48 ±10%

18.0

80 mm

12 to 48 ±10%

18.0

4.5 OVER TEMPERATURE PROTECTION

UL/CSA approved motor over temperature sensing is not

provided by the actuator. Motor over temperature protection

relies on limiting maximum current to the motor and if time-

averaged motor current exceeds a continuous current setting,

the actuator trips or faults and disables the drive indicating a

Continuous Current fault. The continuous current fault level is

set at the factory and cannot be adjusted. These limits are set

to keep the stator below 130 ⁰C while in a stall condition at

40 ⁰C ambient.

The motor contains a temperature sensor embedded in the

stator windings to provide an actual temperature indication.

The actuator trips or faults when the temperature reaches

130 ⁰C and disables the drive indicating an Actuator Over-

temperature fault.

Additional over temperature protection is provided by a sensor

in the drive electronics which generates a fault when the board

reaches 110 ⁰C.

Though some fault conditions may be configured to take action

other than to disable the actuator immediately, reconfiguration

of these two faults is not allowed in order to protect the actuator

motor and electronics.

4.6 I/O POWER SUPPLY

An external I/O Power Supply must be used to provide power

for digital inputs, digital outputs, and the optional holding brake,

if present. On DC models of Tritex TTX actuators, logic power

is not associated with I/O power and there is no internal 24 Vdc

supply from main DC (motor) power, making them significantly

different from AC powered models. The I/O power supply must

have the negative side connected to ground and the positive

side fused at 2 A unless internally limited to 3 A or less. The

I/O power supply is typically 24 Vdc nominal, but other nominal

prevent strands of the braided shield from breaking off and

shorting internal electronics or compromising spacing.

Figure 12

–

Example of a shielding type cable gland.

An Ethernet cable is not required to be shielded, or if shielded,

does not require that the shield is connected at the actuator

end. Do not use a shielded RJ45 jack for an internal connection

to this actuator.

4.3.2 Other Grounding Considerations

Extra-low voltage DC power supplies for I/O circuits or a holding

brake must be ground referenced on the negative side to

prevent stacking voltages where there is more than one source.

Avoid use of independent “Instrument Ground” connections. All

ground connections must run back to a single point.

It is recommended that driven parts are connected to

stationary parts of the machine with grounding jumpers. Some

applications produce static electric charges in the moving parts

of a machine, for example plastic molding, that produce static

charges or impulses that exceed those in EMC tests.

4.4 DC INPUT POWER

4.4.1 Input Power Ratings

The following table shows rated input voltage and current. The

maximum voltage applied to the Tritex TTX080 terminals must

not exceed 53 Vdc from bus to Common and Common must

be tied to PE near or at the power source. Operation on less