HPS-C - TS operating instructions

Page 12 / 32

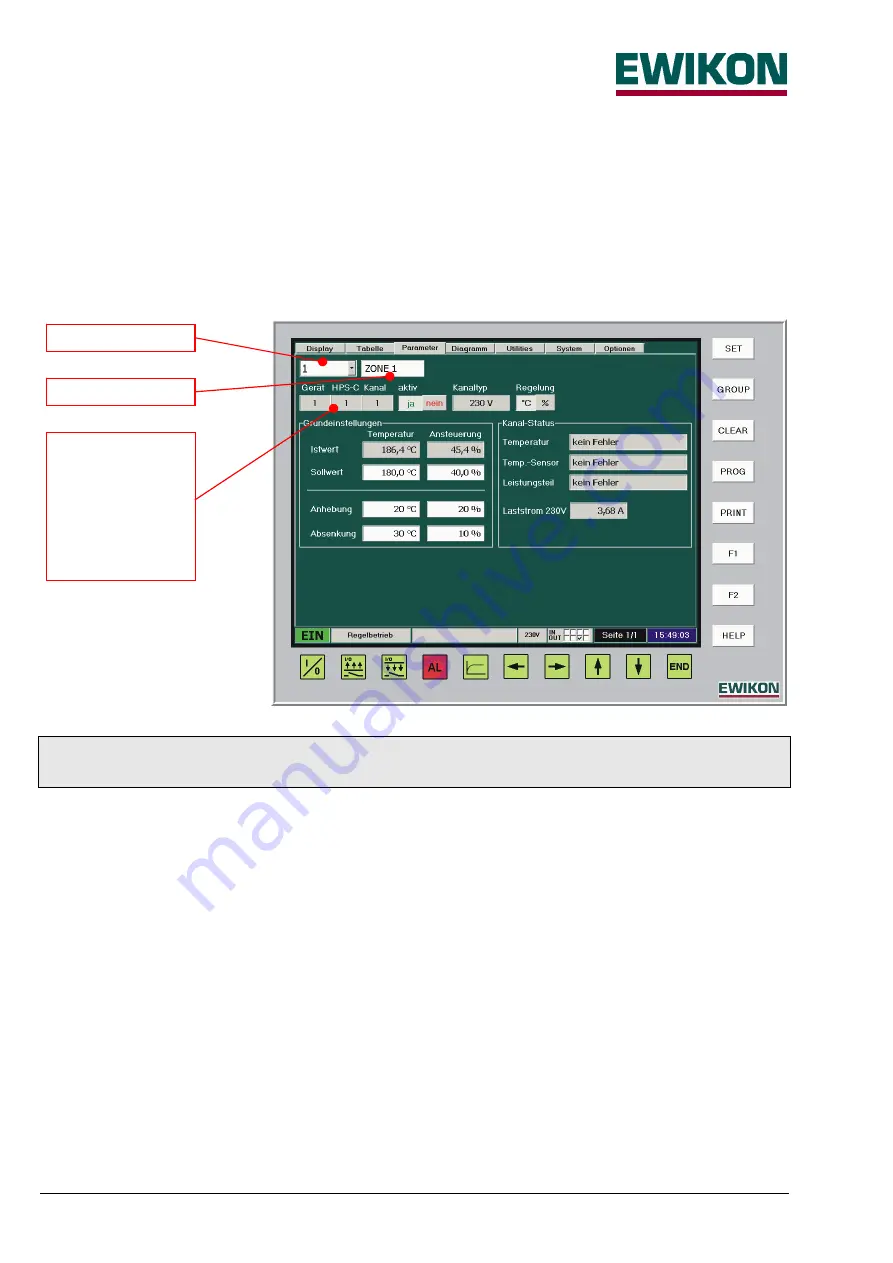

"Parameters" menu

Display

The basic configuration of the controller for the respective application is set in the "Parameters" menu; information about the

zone status is also available here. The zone number, zone name, position within the control system and the operating mode

setting are displayed in the upper part of the screen. Below this there are two other separate areas. The basic settings for

temperature controlled or manual mode are entered in the left-hand side as well as setting the values for increase and

decrease mode. Further, the current actual values of the temperature and output power are displayed. The zone status

information is displayed in the right-hand area.

IMPORTANT: When entering and changing values, ensure that the required zone or group has been selected.

Zone selection

The zones to be changed are selected in the "zone number" field and this might be done in various ways:

•

Select single zones for adjustment. These can be selected using the cursor keys or by pressing the button and setting

the then available slide control. Also, after touching the display field an input window appears, in which the zone

number can be entered directly.

•

Adjusting a group of zones. The zones are grouped in the "Display" or "Table" menu using the method described; the

information "Group" appears in the display. The values of the first zone selected are displayed; all changes made are

applied to all the selected group members. This enables fast adjustment of specific zone groups, e.g. nozzles or

manifolds.

•

Adjusting all zones. The selection is made using the slide control by moving it to the "all" position or by directly entering

the zone number "0". However, this is only possible if there is no more grouping ("CLEAR" key). This function is used

for quickly entering the basic settings of new moulds; however it is also useful for making changes which affect all

zones while the plant is running. The changed values are also applied to inactive zones.

Therefore, this function should only be used to activate zones in certain cases, as it activates ALL the zones in the

control system.

Zone number

Zone name

Position of the

zone within the

control system:

- Device number

- Module in the unit

- Zone number on

the module