Page 16 of 41

Table 2-3

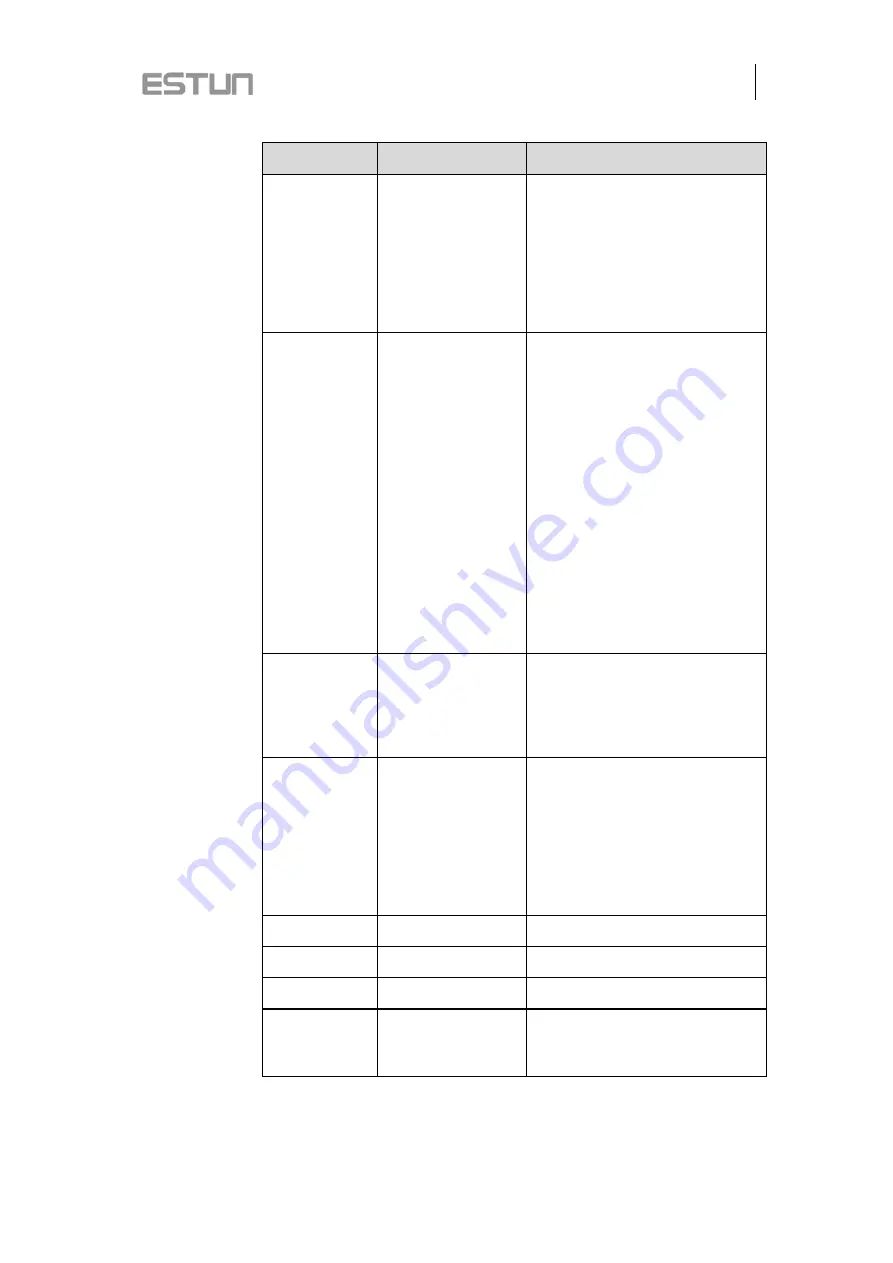

Definition of external output terminal

Terminal No. Signal

Description

1 START

Step change signal, DC +24V

signal input, connect to upper dead

point signal generally, beam return

to upper dead point, +24V signal is

connected, system receive step

change signal, system callout the

next program and execute the

program.

2 PRESS

Back gauge retraction, signal, DC

+24V signal input, avoid

interfering work piece by gauge

device during work. System X axle

positioning is finished, and slider

gets away from upper dead point.

When slide just press against sheet,

retraction signal is connected.

Back gauge will yield some

distance to direction of up counting

(yield distance is determined by

program retraction value), avoid

interference by back gauge and

work piece. When bending is

finished and slide return, back

gauge will return from yield

position.

3 X-EOT

X-axle reference point signal, DC

+24V signal input, connect to rear

limit signal generally. When gauge

touches reference point switch,

+24V signal is connected.

5 COUNT

Piece counting signal, input

DC+24V signal, and connect to

upper dead point signal generally.

Slider return to upper dead point,

+24V signal is connected, one

count is completed. Then signal

must be connected, otherwise the

system will not operate normally.

6 NC1 Retain

7 MRDY Retain

8 NC2 Retain

9 COM1

Common port of system input

signal must be connected to 0V of

I/O power.

Summary of Contents for E21S

Page 2: ......

Page 4: ......

Page 30: ...Page 30 of 41 Figure 5 8 LCD diagnosis page...

Page 34: ......

Page 41: ...Page 41 of 41 Figure 7 4 Demonstration of AC asynchronism motor wiring...