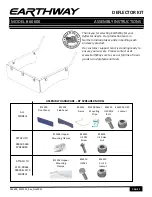

QUICK GUIDE

11

5.3 CHECKING THE BIN WEIGHT ON THE DIGISTAR SYSTEM

1.

Switch on the console.

2.

Repeatedly press select until the SCALE appears on the display.

3.

Press function to increment through the available scales on the system.

5.4 CONNECT THE AIR HOSES TO THE SEEDING IMPLEMENT

1.

Connect the seeding implement’s air hoses to the Air Cart’s distribution system.

2.

Use hose clamps to secure the hoses.

5.5 CALIBRATE THE METERING UNIT

1.

Set the mixer adjustment knob to 100% lower.

2.

Remove the calibration lid on the metering unit.

3.

Fit the funnel bag and container below the metering unit.

4.

Run the calibration program on the ISOBUS control system.

5.

Measure the calibration weight and enter the amount into the control system.

6.

Repeat the calibration process and check that the calibration is indeed correct.

7.

Set the adjustment knob back to the desired position. Ensure that seed metering units

are set to 100% upper.

5.6 SET THE FAN SPEED

1.

Connect the case drain of the fan motor(s) to a dump port on the tractor.

2.

Connect the 1-inch return line to the relevant return line port (dumping port) for constant

oil flow systems, according to the tractor's manual.

3.

Connect the ½ inch pressure line to a standard quick coupler on the tractor.

4.

Set the oil flow rate at the chosen connector to ¼ of its capacity before it can be activated

for the first time.

5.

Make adjustments to the oil flow rate to change the fan pressure reading. Set the fan

pressure for the desired product application rate.

Summary of Contents for AIR CART

Page 1: ...0 OPERATOR MANUAL AIR CART...

Page 5: ...IDENTIFICATION 4 IDENTIFICATION Record the Air Cart s data on the name tag below...

Page 21: ...FRAME 20...

Page 28: ...AUGER 27 Bottom position Side position Spring bolt...

Page 47: ...MAINTENANCE AND INSPECTION 46 9 3 LOCATION OF GREASE POINTS Front steering axle...

Page 48: ...MAINTENANCE AND INSPECTION 47 Auger A Auger bearing B Inner swing arm hinge A B C D E...

Page 53: ...TROUBLESHOOTING 52 SCHEMATICS...

Page 54: ...TROUBLESHOOTING 53...