c

Important:

If stains are wiped off while the surface of the

print head remains dried, the print head may

be damaged. If the surface is dried, return to

Step 5 to apply ink cleaner.

H

Wipe stains off the cleaning wiper, and store it in

a location away from direct sunlight.

I

Close the left maintenance cover.

Next, clean around the caps.

Cleaning Around the Caps

(Daily)

Make sure you clean the wipers (rubber part) first.

This printer has the following cleaning points. Although

numbers may differ from the following illustrations,

make sure you clean everything.

❏

Wiper (x2)

❏

Cap (x10)

❏

Wiper cleaner (x2)

Before starting this procedure, be sure to read the

following:

U

“Precautions Regarding Maintenance” on page 29

Cleaning a wiper (rubber part)

(daily)

Instead of following this procedure, clean the entire

wiper and attachment point once every two weeks.

U

“Cleaning the Entire Wiper and Attachment Point

(Once Every Two Weeks)” on page 37

A

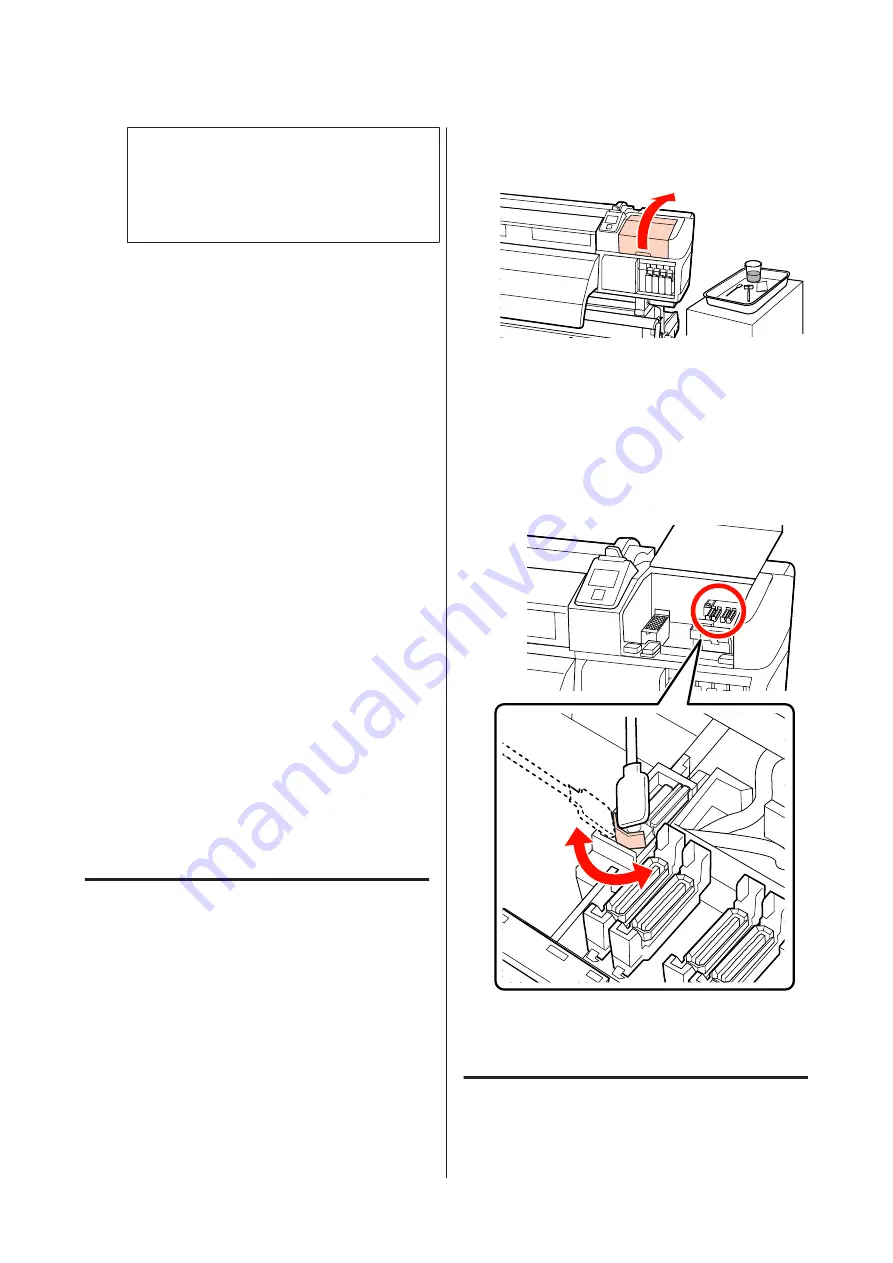

Open the right maintenance cover.

B

Dampen the cleaning stick with ink cleaner.

U

“Using Ink Cleaner” on page 30

C

Clean the front and back of the rubber on the

wiper with a cleaning stick.

Clean the other wipers in the same way.

Next, proceed to the cap cleaning procedure.

Cleaning caps (daily)

Clean both.

EPSON SC-S70600 series/SC-S50600 series Operator's Guide

Maintenance

33