EPSON Stylus Photo R200/R210

Revision A

ADJUSTMENT

Adjustment Items and Overview

77

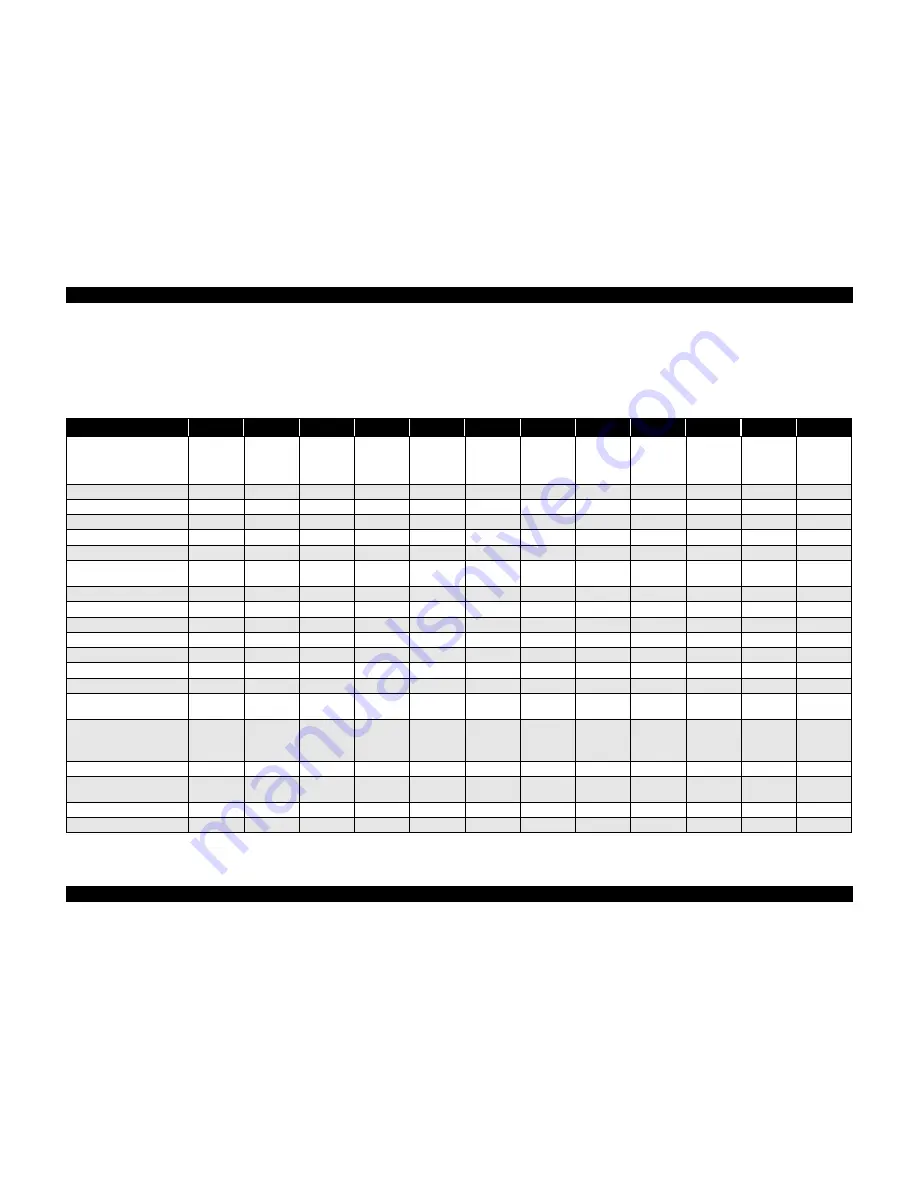

3.1.2 Replacement Part-Based Adjustment Priorities

The following table shows the adjustment items and their order for the replacement

parts.

Note:

"Required" in this table indicates the adjustment items that must be implemented when the

corresponding parts/units have been removed or replaced. "Recommended", on the other

hand, indicates those which are recommended the adjustment after removing or replacing

them. "-" means the adjustment is not needed.

When having removed or replaced more than one part/unit, refer to the items that correspond

to the parts/units.

Table 3-6. Adjustment Item

Performance Priority

1

2

3

4

5

6

7

8

9

10

11

12

EEPROM

Data Copy

Market

Setting

USB ID

Input

Waste Ink

Pad Counter

Ink Charge

Head ID

Input

PG

Adjustment

First dot

Adjustment

PW Sensor

Adjustment

Head

Angular

Adjustment

Bi-d

Adjustment

Offset Input

for CR Motor

Calorific

Limitation

"ASF Unit" Removal

-

-

-

-

-

-

-

Required

-

-

-

-

"ASF Unit" Replacement

-

-

-

-

-

-

-

Required

-

-

-

-

"CR Motor" Removal

-

-

-

-

-

-

-

Required

Required

Recommended

Required

-

"CR Motor" Replacement

-

-

-

-

-

-

-

Required

Required

Recommended

Required

Required

"Paper Guide Upper" Removal

-

-

-

-

-

-

-

-

-

-

-

-

"Paper Guide Upper"

Replacement

-

-

-

-

-

-

-

-

-

-

-

-

"Front Frame" Removal

-

-

-

-

-

-

-

-

-

-

-

-

"Front Frame" Replacement

-

-

-

-

-

-

-

-

-

-

-

-

"CR Unit" Removal

-

-

-

-

-

-

Required

Required

Required

Recommended

Required

-

"CR Unit" Replacement

-

-

-

-

-

-

Required

Required

Required

Recommended

Required

-

"Print Head" Removal

-

-

-

-

-

-

Required

Required

Required

Required

Required

-

"Print Head" Replacement

-

-

-

-

Required

Required

Required

Required

Required

Required

Required

-

"Main Board" Removal

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

"Main Board" Replacement

(Read OK)

Required

-

-

-

-

-

-

"Main Board" Replacement

(Read NG)

-

Required

Required

Required

(Replacing

Waste Ink

Pads)

-

Required

-

Required

Required

Required

Required

Required

"Holder Shaft Unit" Removal

-

-

-

-

-

-

-

-

-

-

-

-

"Holder Shaft Unit"

Replacement

-

-

-

-

-

-

-

-

-

-

-

-

"CR Guide Shaft" Removal

-

-

-

-

-

-

Required

Required

Required

-

Required

-

"CR Guide Shaft" Replacement

-

-

-

-

-

-

Required

Required

Required

-

Required

Required

*1) The adjustment has been completed at the unit level of ASP supply. However, since "Main Board", "Print Head" and "ASF" are supplied separately, refer to the each item that corresponds to the part/

unit.

Summary of Contents for R200 - Stylus Photo Color Inkjet Printer

Page 1: ...EPSON StylusPhotoR200 R210 Color Inkjet Printer SEIJ03014 SERVICE MANUAL ...

Page 5: ...Revision Status Revision Issued Date Description A January 29 2004 First Release ...

Page 7: ...C H A P T E R TROUBLESHOOTING ...

Page 30: ...C H A P T E R DISASSEMBLYANDASSEMBLY ...

Page 72: ...C H A P T E R ADJUSTMENT ...

Page 86: ...C H A P T E R MAINTENANCE ...

Page 96: ...C H A P T E R APPENDIX ...

Page 98: ...Model PM G700 Board C546MAIN Rev F Sheet 1 1 ...

Page 99: ...Model PM G700 Board C546PNL Rev A Sheet 1 1 ...

Page 100: ...Model PM G700 Board C528PSH Rev A Sheet 1 1 ...